Table saws are the beating heart of many woodshops. But if you’re not using the right blade, you’re not going to get the best results.

Have you been dealing with lots of burnt wood and tearout? Your blade choice might be the culprit.

Some of it’s pretty self explanatory.

A ripping blade is meant for ripping (cutting a board lengthwise with the grain). A crosscut blade is for crosscuts (cutting a board across its width across the grain).

But newer woodworkers might wonder, what blades do you actually need? And more importantly, which ones should you get first?

Today, I’m telling you the first 3 (or 4) table saw blades you should buy — in order — and why you need them.

Whether you’re building fine hardwood furniture or banging together plywood cabinets, you’ll find the best blades for the job below.

A NOTE ON QUALITY TABLE SAW BLADES

Before we talk about the types of blades to buy, we need to talk about quality.

It’s worth your time and money to invest in high quality table saw blades.

Like many consumables, cheap blades are only cheap up front. In the long run, they end up costing you more (here’s why).

Good blades resist heat better, stay sharp longer, and can be resharpened multiple times.

Plus, they just work better. Which means you’ll have a better time in the shop.

We carry a collection of high quality table saw blades from CMT Orange Tools. They’re the blades I use, and what I recommend for new and experienced woodworkers.

FULL KERF VS THIN KERF TABLE SAW BLADES

Should you buy full or thin kerf blades? For the most part, it depends on your saw.

Full kerf blades are usually around ⅛” thick, while thin kerf blades are around 3/32”.

On lower power table saws (1.5 hp and below), you should stick to thin kerf blades.

They’ll allow you to get through cuts more easily. With less power, full kerf blades can start to bog down.

On higher power table saws, you can get away with using both — though it’s best to mostly use full kerf blades.

But if you’re working with exotic woods, removing a box lid, or working on a grain wrap, thin kerf blades are great for removing as little material as possible.

YOUR FIRST THREE TABLE SAW BLADES

#1: GENERAL PURPOSE AND COMBINATION BLADES

If you can only get one blade, choose a general purpose or combination blade.

These are the switch hitters of table saw blades — and can be used for both ripping and crosscuts. I think of them as my "all around blades" for projects that don’t need to be absolutely perfect.

They won’t cut as clean as a dedicated rip or crosscut blade, but are perfect for breaking bigger boards into smaller pieces and anytime you’re doing non-repetitive cuts.

General purpose blades hover around 40 teeth, typically have ATB (alternate tooth bevel) teeth, and smaller gullets.

Combination blades hover around 50 teeth, have alternating ATB and FTG (flat tooth grind) or TCG (triple chip grind) teeth, with medium sized gullets.

So how do you choose between one or the other? It depends on the type of woodworking you do.

General purpose blades are best for plywood and boards under 1 ¼” thick.

They’re my go-to blade for making jigs, sleds, and shop furniture.

And if you’re hammering out a project and switching between rips and crosscuts, a general purpose blade is perfect for thinner hard and softwoods.

Combo blades shine when you’re working with thicker lumber — anything over 1 ¼”.

If you’re breaking a thick hardwood board into components for a project, a combination blade lets you bounce between rips and crosscuts with pretty good results.

However, I generally don’t like to use my combo blades on plywood as it can cause more tearout.

Bottom line: If you work with plywood or lumber under 1 ¼” thick, get a general purpose blade. If you work with thicker lumber, get a combo blade.

You can of course get both. But if you have to choose one, just consider the type of woodworking that interests you.

If you need some blades, here's a few we carry:

#2: RIPPING BLADES

I’ll just go out and say it: You need a ripping blade.

Even though I’d get a general purpose or combo blade first, a dedicated ripping blade is just hardly a runner up.

Ripping involves cutting through the length of a board with the long grain — and that means really long cuts.

There’s a lot of potential for heat build up. And if the cut gets too hot, you end up with some serious burning on your workpiece (as in charred black maple that smells like smores).

Also, that heat dulls the teeth of the saw blade. Which leads to more difficult cuts, which leads to more heat… it’s a downward spiral.

Ripping blades hover around 24 teeth, often have ATB and FTG teeth, and have massive gullets.

Fewer teeth lets a ripping blade cut faster. The more quickly you can move through a cut, the less heat can build up.

Plus, the big gullets carry air into the cut and sawdust out, helping cool it down.

In terms of linear feet, ripping is likely most of what you do at the table saw. I cannot emphasize the importance of a good ripping blade.

The first time you use one, you’ll be baffled at how much easier your rip cuts are.

You have a better chance of getting a glue ready finish right off the saw. And it helps increase the lifespan of your other blades by saving them from these long cuts.

Here's a couple options we carry:

But ripping blades are only good for rip cuts. Try to use one to cut a board across the grain and you’ll get aggressive tearout.

That’s where crosscut blades come in.

#3: CROSSCUT BLADES

When you want a super clean cut on end grain edges, a crosscut blade is the way to go.

Crosscut blades often have anywhere from 60-80 teeth, a Hi-ATB grind, and very small gullets.

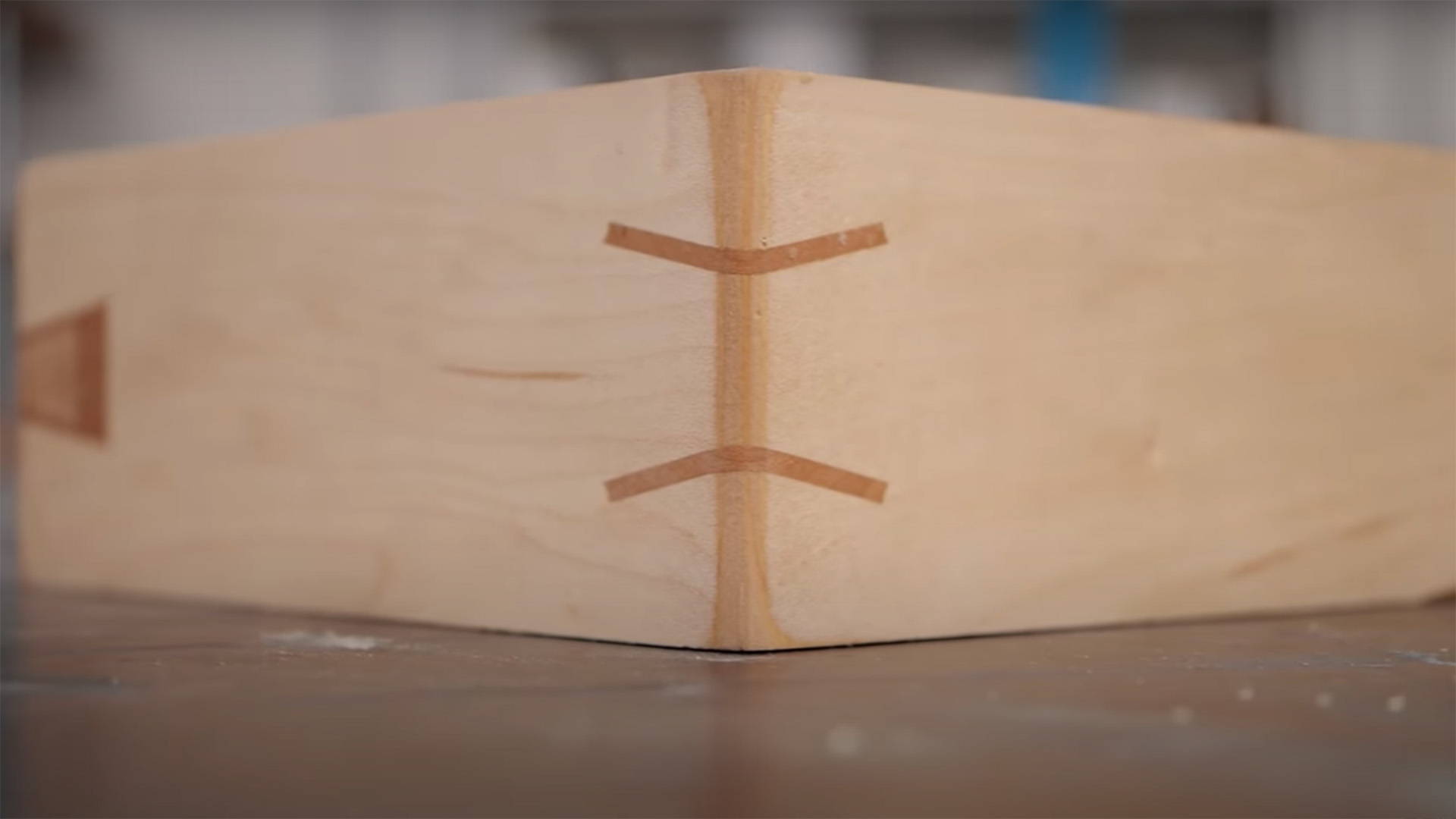

Tearout is the scourge of crosscuts, making it hard to get ultra crisp end grain edges.

But the high number of teeth on crosscut blades severs wood fibers cleanly — and potentially with no tearout at all.

When I’m cutting exposed joinery or need absolute perfection, I use my crosscut blade.

They’re also great for clean cuts in tearout prone materials like plywood.

You can certainly get by without one. But a good crosscut blade makes it a lot easier to get top notch results.

Check out our collection of crosscut blades below:

3 BLADES TO GET YOU STARTED

With the table saw blades listed above, you’ll be well equipped to get excellent cuts in any material.

From there, you can add specialty blades as you develop your skills. A good dado stack is a great addition to your blade arsenal as well.

Want to learn more? Check out our Ultimate Guide to Table Saw Blades for a better understanding of saw blade intricacies and recommendations.

What blade is in your table saw right now? Let us know in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

16 comments

Chris

Oh and disadvantage of thin kerf is that blade flexing can occur much more easily due to a thinner thus weaker blade. Feeding to quickly can cause a cut that’s not square or straight. I’m speaking mainly of rips and with thicker lumber.

Oh and disadvantage of thin kerf is that blade flexing can occur much more easily due to a thinner thus weaker blade. Feeding to quickly can cause a cut that’s not square or straight. I’m speaking mainly of rips and with thicker lumber.

Chris

For Miter saws Rick, go with a crosscut blade. I mean they are used primarily for making cuts across the grain. And make the cut in multiple passes taking shallow passes each time. In addition you can place a zero clearance sacrificial board both underneath the workpiece as well as behind it to virtually eliminate tearout. If the cut’s perfection is extremely vital, do the above but also wrap the cut line with blue painter’s tape for added assurance of a clean cut. Miters are a type of crosscut so a crosscut blade is what to install.

Moonwalk, as for your dado question, I feel that the combo blade works well there. The reason a say that is three little letters, FTG. Okay it was three big letters. And they could also say TCG. Ultimately what you are looking for is a blade that will leave a nice flat smooth surface throughout the dado. You want this in order to obtain a nice, tight fit for the piece to be inserted and for it to be ready to glue up without having to clean it up with a chisel or sandpaper. Anything that says only ATB (which is most every blade out there it seems or is at my small town Lowe’s) is a terrible choice for cutting dados. As a matter of fact, if all I had was a blade that was ATB, I’d probably break out the trim router and a 3/4" straight cut bit (or whatever size is appropriate and sneak up if necessary) and clamp a small level or straight board as needed for the router.

Last, for those who find using a thin kerf blade causes binding, so did I. The solution I went with was splitters! Yes, you can on rare occasions find the right size thin kerf riving knife or someone to custom one. But splitters can be swapped out for the appropriate size per blade very easily. The trade-off is the inability to use the blade guard or worse, the anti-kickback pawls. After gaining a little practice however, I find I rarely use either of those. As long as your saw is calibrated and square and especially if using a pushblock such as the grrriper along with a good featherboard (I love my green one with the replaceable foam inserts), then fingers should remain attached and kickback is very very unlikely. Plan your cuts. Walk through the process in your head over and over. Do dry runs to make sure your Block or stick won’t contact the blade. Be sure before you fire up the saw. Even still though, surprises can occur. Which is why I sometimes use a momentary foot switch as a “dead man switch”. Must be depressed to start saw and if you release it, it cuts the saw and it won’t restart again until the foot pedal is pressed and the saw start switch is pressed. So if something starts to feel funny, I lift my foot off the switch. Oh and make a crosscut sled. It makes most of this irrelevant.

For Miter saws Rick, go with a crosscut blade. I mean they are used primarily for making cuts across the grain. And make the cut in multiple passes taking shallow passes each time. In addition you can place a zero clearance sacrificial board both underneath the workpiece as well as behind it to virtually eliminate tearout. If the cut’s perfection is extremely vital, do the above but also wrap the cut line with blue painter’s tape for added assurance of a clean cut. Miters are a type of crosscut so a crosscut blade is what to install.

Moonwalk, as for your dado question, I feel that the combo blade works well there. The reason a say that is three little letters, FTG. Okay it was three big letters. And they could also say TCG. Ultimately what you are looking for is a blade that will leave a nice flat smooth surface throughout the dado. You want this in order to obtain a nice, tight fit for the piece to be inserted and for it to be ready to glue up without having to clean it up with a chisel or sandpaper. Anything that says only ATB (which is most every blade out there it seems or is at my small town Lowe’s) is a terrible choice for cutting dados. As a matter of fact, if all I had was a blade that was ATB, I’d probably break out the trim router and a 3/4" straight cut bit (or whatever size is appropriate and sneak up if necessary) and clamp a small level or straight board as needed for the router.

Last, for those who find using a thin kerf blade causes binding, so did I. The solution I went with was splitters! Yes, you can on rare occasions find the right size thin kerf riving knife or someone to custom one. But splitters can be swapped out for the appropriate size per blade very easily. The trade-off is the inability to use the blade guard or worse, the anti-kickback pawls. After gaining a little practice however, I find I rarely use either of those. As long as your saw is calibrated and square and especially if using a pushblock such as the grrriper along with a good featherboard (I love my green one with the replaceable foam inserts), then fingers should remain attached and kickback is very very unlikely. Plan your cuts. Walk through the process in your head over and over. Do dry runs to make sure your Block or stick won’t contact the blade. Be sure before you fire up the saw. Even still though, surprises can occur. Which is why I sometimes use a momentary foot switch as a “dead man switch”. Must be depressed to start saw and if you release it, it cuts the saw and it won’t restart again until the foot pedal is pressed and the saw start switch is pressed. So if something starts to feel funny, I lift my foot off the switch. Oh and make a crosscut sled. It makes most of this irrelevant.

Paul

Very helpful guide! I have a question about the riving knife. Since switching to thin kerf blades, it’s been difficult to use the riving knife on rip cuts because it is thicker than the blade and tends to bind up on longer rip cuts. It’s an important safety feature that I do not like to remove. Does anyone know if there are thin-kerf riving knives available anywhere?

Very helpful guide! I have a question about the riving knife. Since switching to thin kerf blades, it’s been difficult to use the riving knife on rip cuts because it is thicker than the blade and tends to bind up on longer rip cuts. It’s an important safety feature that I do not like to remove. Does anyone know if there are thin-kerf riving knives available anywhere?

David Etherington

What are the disadvantages of a thin-kerf blade?

What are the disadvantages of a thin-kerf blade?

Raleigh

1 for Dado and +100 for Forrest. The dado is without a doubt the 2nd most common cut I do. To be honest, I’ve been working cabinets and furniture for 30 years on a single Forrest Woodworker Ii blade, a forrest dado stack, and a thick kerf freud for chewing 8/4 hard maple. Sawstop owners may need to pickup the cartridge but I can’t imagine life without the dado stack.

1 for Dado and +100 for Forrest. The dado is without a doubt the 2nd most common cut I do. To be honest, I’ve been working cabinets and furniture for 30 years on a single Forrest Woodworker Ii blade, a forrest dado stack, and a thick kerf freud for chewing 8/4 hard maple. Sawstop owners may need to pickup the cartridge but I can’t imagine life without the dado stack.

Botch

I bought a Forrest “Woodworker II” 40-tooth over 30 years ago, and it still cuts beautifully; I’ve never had it sharpened or even cleaned! (granted, my career kinda got in the way a lot). Now that I’m retired, maybe its time to sharpen/add, I’ve got a list of projects to do…

I bought a Forrest “Woodworker II” 40-tooth over 30 years ago, and it still cuts beautifully; I’ve never had it sharpened or even cleaned! (granted, my career kinda got in the way a lot). Now that I’m retired, maybe its time to sharpen/add, I’ve got a list of projects to do…

Matt D

Running a Delta 36-725 table saw with CMT Orange ITK thin-kerf 50 T combo blade, a Diablo dado stac,k and a Dewalt 60T thin kerf fine-finish plywood blade.

Running a Delta 36-725 table saw with CMT Orange ITK thin-kerf 50 T combo blade, a Diablo dado stac,k and a Dewalt 60T thin kerf fine-finish plywood blade.

Grant

Right now I have a Sawstop combination blade on my Sawstop contractor saw (not the job site saw). I also have both thin and full kerf rip blades, both are Freud. The problem with a thin kerf blade on a Sawstop is that the blade guard is 1/8” and that extra 1/32” causes it to bind the wood against the rip fence. The solution is either to remove the guard or slide the fence to the left of the blade, which feels like left hand work to me. Good information in the post, however.

Right now I have a Sawstop combination blade on my Sawstop contractor saw (not the job site saw). I also have both thin and full kerf rip blades, both are Freud. The problem with a thin kerf blade on a Sawstop is that the blade guard is 1/8” and that extra 1/32” causes it to bind the wood against the rip fence. The solution is either to remove the guard or slide the fence to the left of the blade, which feels like left hand work to me. Good information in the post, however.

Bill K.

Currently, I’m using the CMT combination blade in a SawStop Jobsite Pro saw. Working well for me.

Currently, I’m using the CMT combination blade in a SawStop Jobsite Pro saw. Working well for me.

Link Dickerson

I agree with you with 1 caveat. I think every new woodworker should have a dado stack if they’re saw with support it. Using them opens up doors to thinking and possibilities.

Even having a yard sale craftsman dado stack is worth it. Dado and rabbet cuts don’t have to be one and done exactness though that is often how they are presented. You can sneak up on the exact fit like any other table saw cut.

My 2¢. Your mileage may vary.

I agree with you with 1 caveat. I think every new woodworker should have a dado stack if they’re saw with support it. Using them opens up doors to thinking and possibilities.

Even having a yard sale craftsman dado stack is worth it. Dado and rabbet cuts don’t have to be one and done exactness though that is often how they are presented. You can sneak up on the exact fit like any other table saw cut.

My 2¢. Your mileage may vary.

Rick

Hi, which blade (teeth count) do you recommend for a 10" miter saw( older craftsman, looking at up grading to the Bosch ) thanks, rick

I’m still pondering because of the exchange rate & shipping

Hi, which blade (teeth count) do you recommend for a 10" miter saw( older craftsman, looking at up grading to the Bosch ) thanks, rick

I’m still pondering because of the exchange rate & shipping

Jim Q_Moonwalker

Thanks for the great summary. I do not have a dado blade stack yet. From this article I found your Ultimate Table Saw Blade Guide article. What is the best blade to use (other than a dado stack) to cut dados on my table saw? You mention both the ATBR combination blade or FTG ripping blade. Thanks you!

Thanks for the great summary. I do not have a dado blade stack yet. From this article I found your Ultimate Table Saw Blade Guide article. What is the best blade to use (other than a dado stack) to cut dados on my table saw? You mention both the ATBR combination blade or FTG ripping blade. Thanks you!

Joe

I’ve got a Freud Industrial glue line ripping blade on my saw right now, with a 60 or 80 tooth count blade on my radial arm saw for crosscutting. I also have dedicated blades for plywood/mdf sheet goods. Mostly Freud or Oshlun blades right now. Haven’t tried CMT’s stuff.

I’ve got a Freud Industrial glue line ripping blade on my saw right now, with a 60 or 80 tooth count blade on my radial arm saw for crosscutting. I also have dedicated blades for plywood/mdf sheet goods. Mostly Freud or Oshlun blades right now. Haven’t tried CMT’s stuff.

Patrick Daniels

Great piece Johnathan! A number of people have found using smaller versions, rather than a 10” bade is extremely efficient, especially in jobsite versions of table saws. Well worth a mention here.

Thanks for all you do!!

Great piece Johnathan! A number of people have found using smaller versions, rather than a 10” bade is extremely efficient, especially in jobsite versions of table saws. Well worth a mention here.

Thanks for all you do!!

Matt

I’ve been using the CMT combo blade on my contractor saw and it works great! I keep a crosscut blade on my miter saw. And I have a ripping blade that came with my saw but haven’t used much – looks like a thin kerf ripping blade will go in my next order!

I’ve been using the CMT combo blade on my contractor saw and it works great! I keep a crosscut blade on my miter saw. And I have a ripping blade that came with my saw but haven’t used much – looks like a thin kerf ripping blade will go in my next order!

Bob

If you have all three blades, which do you go with for large pieces of 3/4" plywood? Because of cut length I could see benefit of the ripping blade. Because of tear out I could see using the cross cut blade. Do you just use your combo or general purpose? Or use the cross cut and go slowly? Thanks!

If you have all three blades, which do you go with for large pieces of 3/4" plywood? Because of cut length I could see benefit of the ripping blade. Because of tear out I could see using the cross cut blade. Do you just use your combo or general purpose? Or use the cross cut and go slowly? Thanks!