Want to add strength and a decorative touch to your miter joints? Splines are just the ticket.

Miter joints are simple to make and look beautiful. But they aren’t very strong.

The 45° edges expose a lot of end grain — and that can become a failing point when you rely on just glue.

Splines add a ton of strength and aesthetics to your miter joints. Best of all, they’re super simple to cut.

Today, I’m going to explain how to make splined miters — from building a jig that makes it easy, to 3 ways you can cut more interesting splines.

This is a super useful technique if you’re into box making. So let’s get to it.

HOW TO BUILD A MITER SPLINE JIG

This jig is easy to make and can be used on your table saw or router table.

All you need is some scrap plywood (just make sure it’s flat).

I like to build the jig in two pieces. This makes it easier to get right, and even lets you replace the face of the jig for other operations.

The first piece is just a three-sided box that fits around your table saw fence. You want it tight, but loose enough to be able to slide back and forth.

The face piece is what will hold your box in position at 45°.

STEP 1: CUT THE FENCE SLIDER PIECES

Rip two pieces of plywood so they’re a little wider than the height of your table saw fence.

The width doesn’t need to be exact, but make sure they’re the same and have parallel edges.

Butt both of these pieces against your fence with two business cards between them (this will make sense later). Then put a piece of plywood flat against the fence on the opposite side.

Use a square to measure the distance from the outside of the two pieces you cut to the face of the other piece of plywood.

This will be the width of the top piece, so lock the square down tight. Use it to set up the fence of your table saw for a rip cut and cut your top piece.

The length of the pieces isn’t critical. I made mine about 10” long.

STEP 2: ASSEMBLE THE FENCE SLIDER

Place a side piece on either side of the fence with a business card shimmed between. This ensures the slider will be tight but can still slide.

I use two clamps to lightly hold the side pieces in position. Make sure their bottom edges are flat on the table top and that the outside faces are square.

Spread a line of super glue on the top edges of both pieces. Don’t put too much — you don’t want any squeeze out.

Place the top piece so it rests on the side pieces. Make sure it’s flush on both sides. If you can only get one side flush, choose the one closest to the table saw blade.

Hold it in place for 30 seconds to a minute while the glue dries. Then put some screws through the top to secure everything together.

STEP 3: BUILD THE FACE PIECE

The face piece is what your box will lay on. Make sure it’s flat, big enough to handle your box, and has at least one straight edge.

Mark a point in the middle of the straight side. It doesn’t need to be the exact center, but close.

Starting from this point, use the 45° fence on a combo square to mark two lines with a pencil.

Make sure you start the two lines at the same point. This is what will let the corner of your box reach the table. If you have to err one way, draw the lines closer together, not farther apart.

Now you need two pieces of scrap to make the support fence. I like these to be around 2”-3” wide.

Put super glue on the edge of one piece and set it so it lines up with the 45° pencil lines. You can use your square to make sure it’s aligned.

Repeat the process with the other piece and let the glue dry. Once it does, secure it with a couple countersunk screws through the back.

STEP 4: ATTACH THE FACE PIECE TO THE SLIDER

Place the slider piece on the fence, making sure the edges are flat on the table.

Now butt the face piece against the side piece closest to the blade. Make sure the bottom edge is flat on the table, then attach with countersunk screws.

The face should be 90° to the table top, but check to make sure. If it isn’t, loosen the screws and use shims to get it as close to square as possible.

That’s it! You’ve now got a fully functional spline jig.

HOW TO PREPARE SPLINE MATERIAL

There are two important points when making material for splines:

- GRAIN DIRECTION: In order to add strength, splines need to take advantage of long grain. The long grain edge should be in the bottom of the cut — i.e. the end grain should NOT be facing the same direction as the corner.

- THICKNESS: The spline’s thickness should be as close to your blade kerf as possible. That said, you don’t want it so tight it won’t fit once you add glue.

The best way to cut splines depends on your tools and abilities.

A power planer can work, but the blade kerf might be too thin in some cases.

On the table saw, you can use a thin rip jig to quickly cut spline material. A bandsaw also works well (though the splines might be a little rougher).

You can also grab a rip saw and hand plane to do it the old fashioned way.

I like to make my splines with a contrasting wood species from my box. For example, walnut splines in a white oak box.

The contrast really makes them pop. But if you prefer splines to be more muted, use an offcut from your project.

HOW TO MAKE A MITER SPLINE

Once your jig is built and splines are ready, making a miter spline is quick and easy. Here’s what to do.

1. LAY OUT YOUR SPLINES

How you layout your splines is entirely up to you. But two splines at the same distance from the top and bottom of a box is the easiest.

With the jig, you don’t even have to measure. Just set your fence so the table saw blade cuts one spline. Then flip the box around without adjusting anything and make a second cut.

Your two splines will be evenly spaced.

If you want to do more than two equally spaced splines, here’s a little trick for laying them out.

Measure the distance from the box’s bottom to top edge, then divide that distance by one more than the number of splines you want.

For example, say your box edge is 5” wide and you want 4 equally spaced splines.

Divide 5” by 5 (4+1) and you get 1”. Measure 1” in from each side to mark the two outside splines, then 1” in from that point for your inner splines.

Once you decide on your layout, set your fence so the box will pass over the blade at the right point when sitting in the jig.

2. SET YOUR CUTTING DEPTH

The bigger the cutting depth (i.e. the higher the blade), the further your spline will extend across both sides.

This is entirely a design choice. But make sure your cutting depth isn’t so high that you cut all the way through the corner.

(I’ve actually done this intentionally to create an upper shelf support on some boxes… so really do whatever the heck you want).

The type of table saw blade also makes a difference. Ideally, use a blade with at least one FTG (flat top grind) tooth. A lot of ripping blades have this.

The flat tooth leaves a flat bottom to your cut, which allows the spline to fully seat. ATB (alternate tooth bevel) blades leave a hump in the middle which can create a gap.

If you don’t have any blades with FTG teeth, you can use the depth stop on Japanese pull saws to flatten out the bottom of the cut (here’s how).

3. CUT THE SPLINE RECESSES

Now that everything is set up, it’s go time.

Place your box on the face of the jig so it’s supported by the two 45° fences.

As you push the box through the blade, keep pressure on it in two directions — sideways into the jig’s face and down into the 45° fences.

Once you’re ready to go, turn on the table saw and make the cut.

If you’re doing this on the router table, the jig slider might not fit around the fence. That’s ok.

Just keep one side of the slider flat against the router table fence as you cut.

If you’re doing two evenly spaced splines, flip the box around without adjusting anything and make a second cut. Repeat the process for all four corners.

TEAROUT TIP

If you’re getting tearout where the blade exits the cut, grab a roll of blue painter’s tape.

Put a strip on the back edge where the blade will exit before making subsequent cuts. This will help keep the fibers in place and stop any splintering.

4. GLUE IN THE SPLINES

Cut your spline material into smaller pieces to fit each recess. You can leave them rectangular for now — we’ll flush cut them later.

Add a bit of glue to both surfaces and the back edge (don’t overdo it), then slide the spline into place.

Let it sit for a half hour or so to dry. This is a good time to clean up as much squeeze out as you can with a damp rag.

5. FLUSH CUT THE SPLINES

Once the glue’s dry you can trim the splines flush.

I like to do this with a flush trim saw with no tooth set.

But if you don’t have one, here’s a few other ways to flush trim proud joinery.

Now just sand or plane the surfaces smooth and you’re ready to add finish.

OTHER CREATIVE SPLINE IDEAS

Your miter splines don’t have to be simple straight lines.

Here’s some ways to spice them up and add a bit more intrigue to your project.

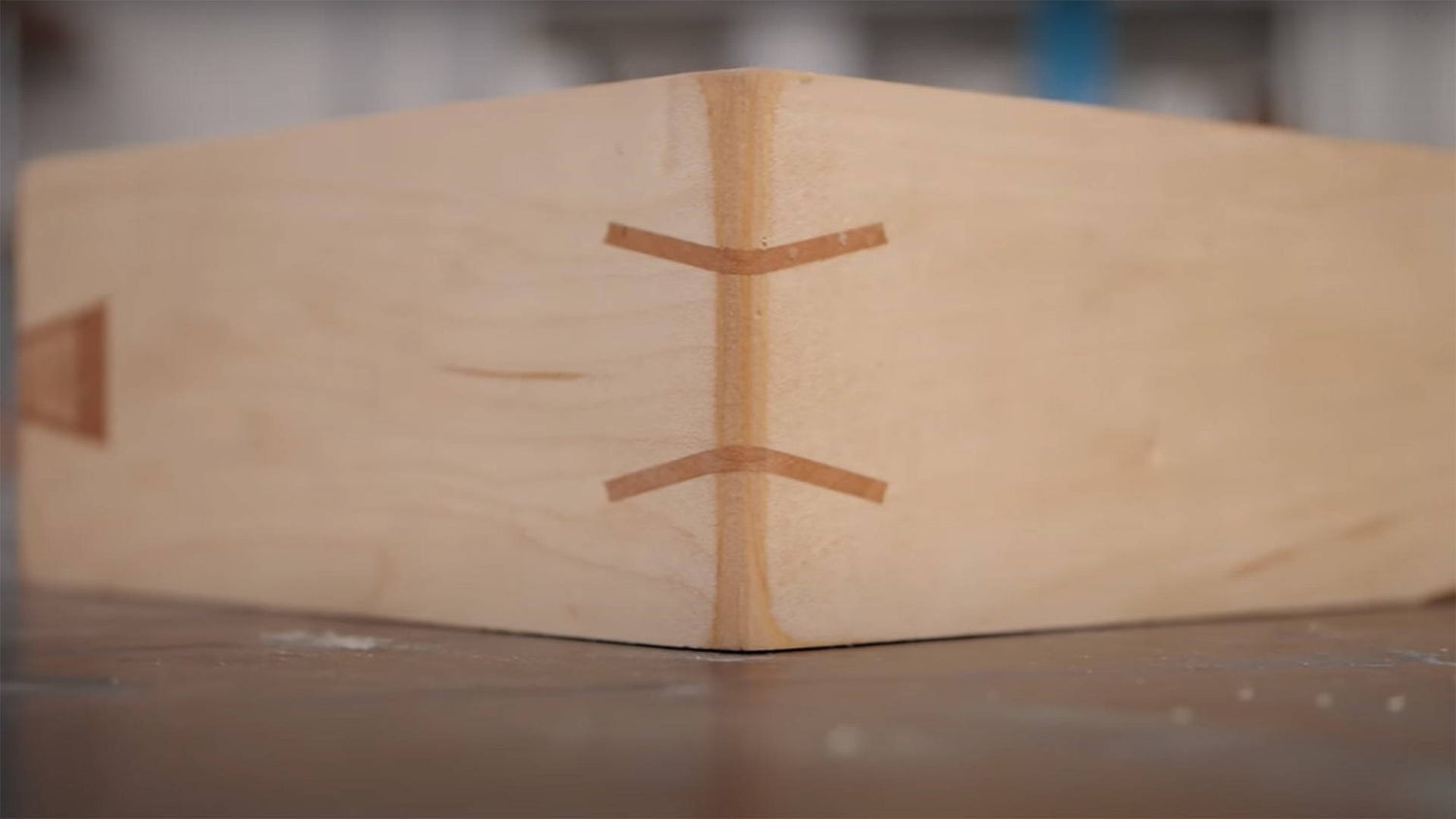

ANGLED SPLINES

Angled splines create a super cool v-shaped inlay look — and they’re dead simple to do.

All you need to do is set your table saw blade at an angle.

The angle can be anything at all. I usually do around 15°-20°, but experiment with different angles for different looks.

From there, just follow all the same steps as you normally would.

DOVETAIL KEY SPLINES

Dovetail key splines are straightforward to cut on the router table. All you need is a dovetail bit.

Position the router table fence and bit height where you want them, then use your spline jig to make the cut.

When you go to cut the key, DO NOT adjust the height of the router bit. It needs to be the same to match the recess.

Get a piece of wood that’s wide enough to safely pass across the bit. You don’t want your fingers getting close.

Also be sure to use two push sticks. One keeping the board flat on the table, and another keeping it flat against the fence.

Make a cut on one side so the full profile of the dovetail bit shows.

Then flip the piece around and keep making passes until the key fits.

Make a pass, test the fit in the recess, bump over the fence, and cut again.

Test and repeat until the key fits snugly.

Then cut the key off your stock, making sure to cut it proud. Glue it in, flush trim the excess, and you’re done.

INLAID DOVETAIL KEY SPLINES

These look really cool and will have people wondering how the heck you did it.

First, follow all the steps of a regular dovetail key spline listed above.

Now find a smaller dovetail bit with the same angle (I used 14°).

Set up your fence so this cut will be centered in the first key you cut, then repeat the regular dovetail key process.

The results are awesome — and all you have to do is repeat a few steps.

SPLINE THE NIGHT AWAY

Splines are an easy and beautiful way to strengthen miter joints.

There’s no limit to how creative you can be with them. So don’t be afraid to experiment and get a little weird.

Looking for a sturdier way to build boxes? Try your hands at some dovetails! They’re way sturdier than miter joints and a great way to develop your hand tools skills.

What’s your favorite way to cut miter splines? Let us know in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!