Ever feel like your projects take longer than they should?

That’s partly the cold hard truth of woodworking. But another reason could be your shop layout.

Shop layout and organization plays a massive role in how quickly you finish projects — and enjoy building them.

But there’s no one-size-fits-all approach. The best design depends on your square footage, the tools you have, and the type of woodworking you do.

That said, there are principles that maximize your space and efficiency — whether your shop is a warehouse or a Harry Potter closet under the stairs.

After setting up and working from four different woodshops (from 120 to 2500 square feet), I’ve learned a few things about shop layout…

And today, I’m giving you my Top 5 Tips for smarter shop set up — so you can streamline your workflow and get more projects done.

Download our free shop layout planning tool. Just print and cut out the pieces and you can easily visualize your new shop set up.

1. THINK IN CLUSTERS

The first rule of shop layout: Put tools that get used together close together.

That means grouping tools, accessories, and consumables by the operation or stage of a project they’re used for.

Even if your shop is tiny, this adds efficiency to your workflow. You can get a whole section of a project done without needing to walk across your shop.

I organize my shop into five main tool clusters:

MILLING CLUSTER

Milling is the start of every project where you make lumber flat, straight, and square.

And since milling has a clear order of operations, it makes sense to cluster the following tools together:

- Miter Saw

- Jointer

- Planer

- Table Saw

If you have a lot of space, store your lumber close to the milling cluster. That way, you don’t need to lug massive boards from one side of the shop to the other.

TEMPLATE CLUSTER

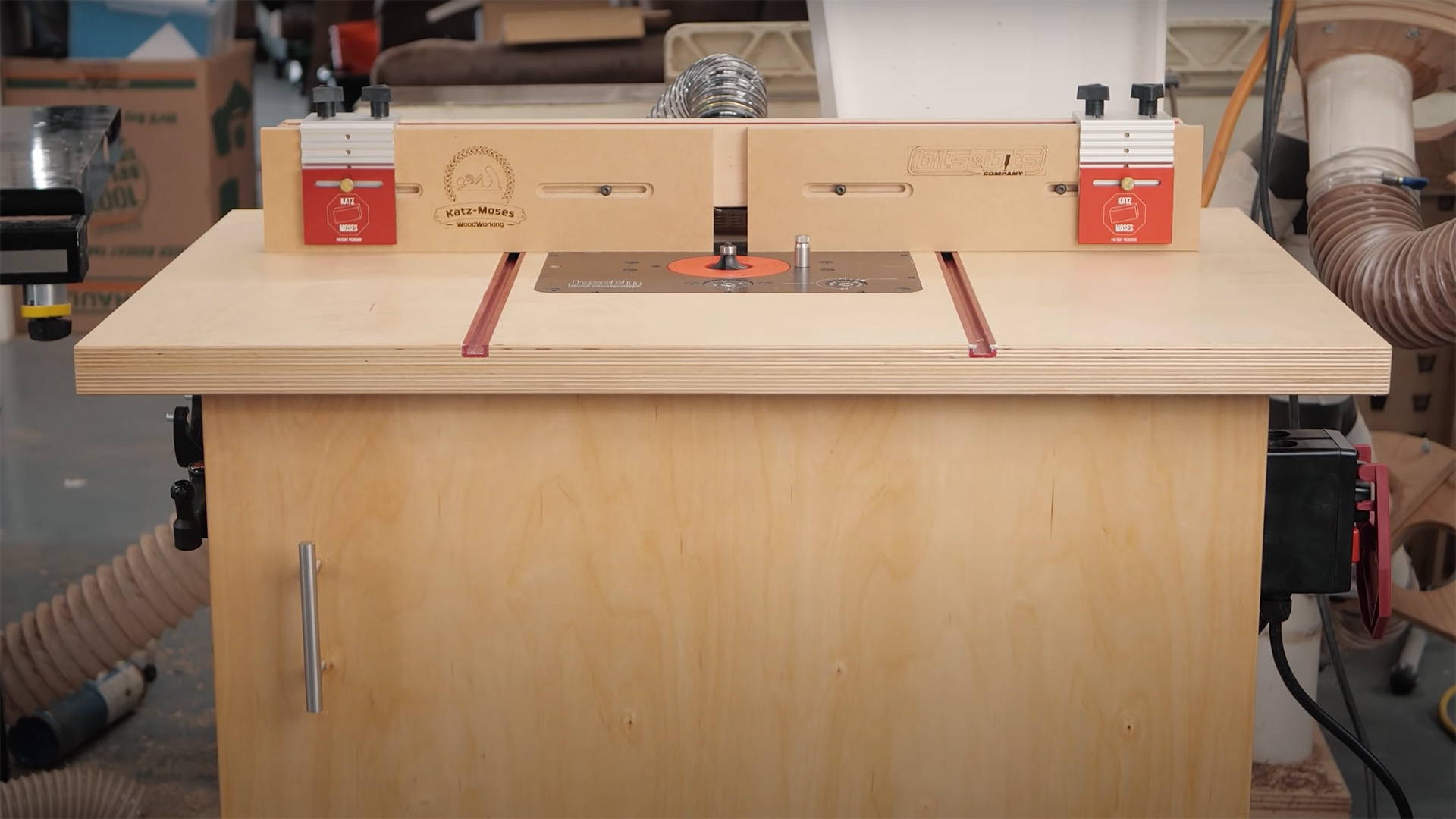

If you do a lot of template routing, keep these tools together:

- Band saw

- Router table

- Spindle and stationary belt sander

You’ll rough cut your templates at the bandsaw, then dial in the curves with one of the stationary sanders. From there, you’ll go back to the bandsaw to cut your workpiece to the template, then finish it on the router table.

Again, figuring out the best way to layout your tools is all about understanding how you move around the shop during a project.

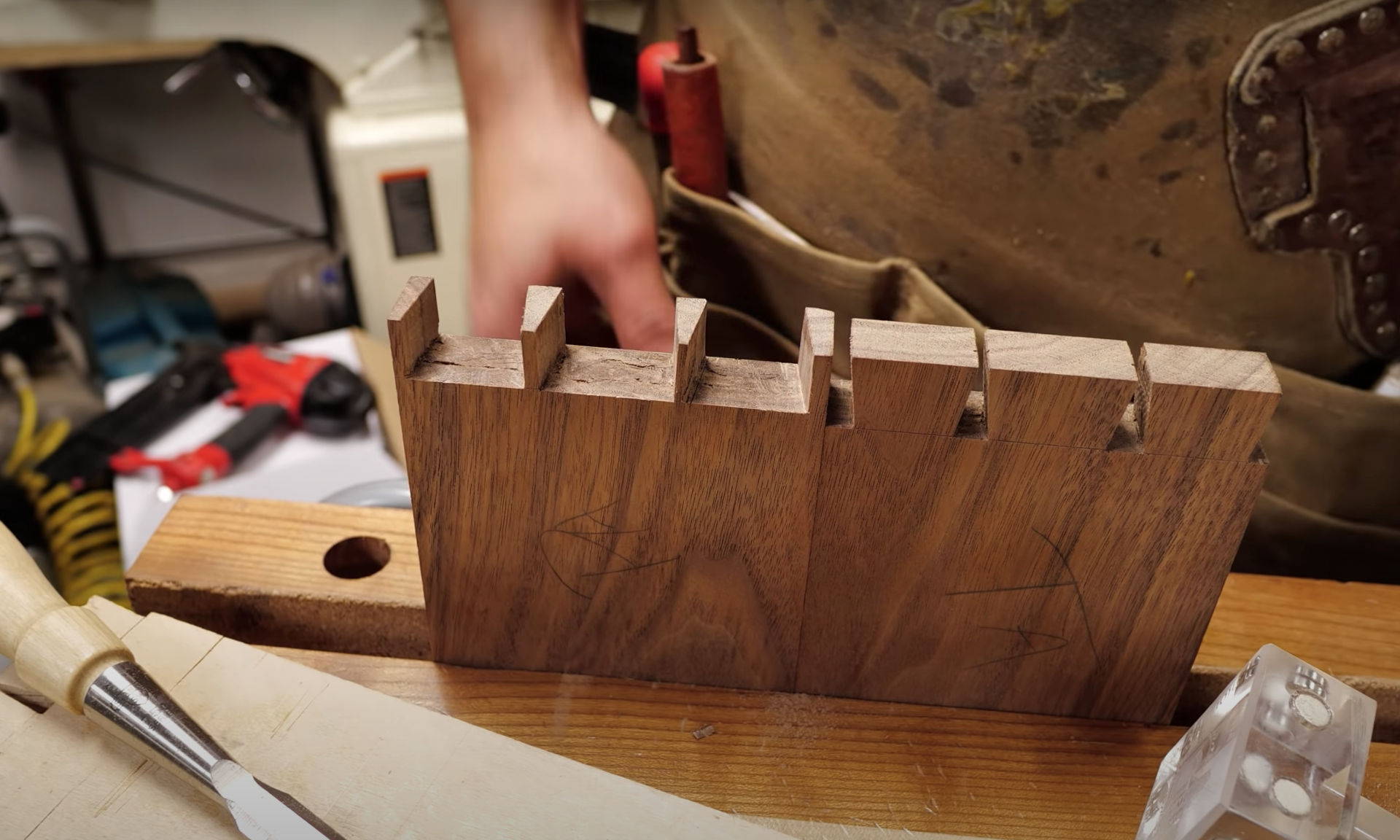

HAND TOOL CLUSTER

If you’re hand tool focused, a joinery workbench will be the central point of your shop.

Wherever you place it, make sure your hand tools are close at hand.

If your workbench is close to a wall, create a shelving system for your tools.

Or if your workbench is in the middle of your shop, build integrated storage for your most used tools.

PLYWOOD BREAKDOWN CLUSTER

Work a lot with plywood? Keep everything you need for breaking it down in one place, including:

- Track saw and tracks

- Framing squares

- Foam base for cutting on

- Clamps for holding work steady

- Saw horses

Since so much plywood work is done on the table saw, I use my outfeed table as a plywood breakdown area.

I also keep a couple saw horses nearby (here’s a video on building the ultimate saw horse).

ASSEMBLY CLUSTER

This is where I sand, add profiles, assemble, and finish projects. It’s all centered around my assembly table.

Things I keep around here include:

- Drill press and hand drills

- Sandpaper and handheld sanders

- Routers with edge profile bits

- Clamps

- Glue and tape

- Finishes

This might also be a good spot for a shop vac so you can get dust collection on your sanders.

2. CONSIDER ELECTRICAL, DUST COLLECTION, AND LIMITATIONS

When you're deciding where to place power tools, first consider your outlets.

Plug tools directly into outlets wherever possible. If you have to use extension cords, make sure they’re the right gauge and the shortest length possible so your tools get enough power.

(My first shop had zero power and I had to run everything through a 50 ft extension cord. Not ideal, but it’s definitely doable).

Your dust collector will also dictate tool placement.

A powerful dust collector will have no problem creating adequate suction across multiple lines meandering around your shop.

But if your dust collector is 1hp or less, it might be better to keep it and your big tools close together so you can run short lines.

Efficient dust collection is a topic in and of itself. Watch this to learn all about dust collection.

Spacing around your tools is another thing to keep in mind.

Leave enough space on the infeed and outfeed sides of your tools to accommodate the longest boards you normally work with.

For most people, 8 feet of clearance on either side of the bladeshould be plenty.

On our free printable layout tool, we used red boxes to mark 8 ft on both the infeed and outfeed sides of your tools.

3. GET HIGH, GET LOW

Put down the doobie. We’re still talking shop layout.

When it comes to lumber and smaller tools, you’ve got to look beyond floor space.

Wall storage is an absolute life saver. Especially in small shops.

French cleat systems are one of my favorites. They’re super easy to build and can be adapted to hold anything from hooks, to shelves, to full sized cabinets.

Here’s a video of the french cleat clamp rack system I put together (plus free plans).

Peg boards are another easy way to maximize vertical storage, as well as wall-mounted lumber racks.

There might even be ways to turn your ceiling into functional storage space. Store lumber in the rafters, or find ways to hang certain tools above your bench.

(Just make sure nothing can fall and that you don’t make a chandelier of death).

Don’t forget to look down as well.

Under-tool storage is beyond useful. Not just to clear clutter, but to make you more efficient.

A cabinet underneath your table saw’s extension table is perfect to store saw blades, push sticks, featherboards, and other accessories always in arms reach.

In fact, we’ve got plans for a storage cabinet that fits under the extension wing and has a special vertical drawer for storing your table saw blades. Check them out here.

4. MAKE THINGS MULTIFUNCTIONAL

In a massive shop like mine, I can get away with having an outfeed table, assembly table, joinery bench, and more.

But I had a tiny shop (i.e. shed) for years. I know from personal experience that in small spaces, you need to be a little more creative.

If your shop is only big enough for one bench, make it into an Optimus Pine of shop benches.

Add heavy duty casters and make it the same height as your table saw. Now it can double as an outfeed table.

(I know some people rail against putting casters on your workbench, but it’s worth it if you’re in a small shop. Just get good quality ones that lock tight).

Put a big roll of wax paper at one end you can use to cover the top during glue ups and save yourself clean up time.

You could even build a router table into one side of your workbench — or a mini-bar, or a massage station (ok…getting carried away).

Point is, limited space doesn’t have to limit what you do. It just means you have to be more creative with your solutions.

5. MAKE YOURSELF A WALKING TOOL CHEST

The absolute game changer in my efficiency as a woodworker? My tool apron.

We all know the frustration of searching for a tool you set down literal seconds ago.

A good apron saves you from those moments. No matter where you are in the shop, your most used measuring and marking tools are always on hand.

And by becoming a walking toolbox, you gain more storage around the shop for other tools.

The Katz-Moses Tool Apron has 12 pockets (from pencil to beer can sizes), 2 hammer loops, and dedicated leather holsters for your square and marking knife.

Even when you're laden with tools, the fully adjustable straps and padded shoulder supports make it super comfortable. And it’s built to last under heavy use and abuse.

BONUS TIP: CHAOS TABLES

A core tenet of shop organization is “A home for everything and everything in its home.”

But what about the odds and ends that accumulate? That’s why I believe your shop needs at least one dedicated “chaos table.”

It’s literally just a table where you pile up all the stuff that doesn’t have a home. Cups of coffee. Mail you’ll never open. The exotic offcut you know you’ll never use but can’t bring yourself to throw away.

Just one small table to absorb the chaos will go a long way in keeping the rest of your shop clean — and save you from constantly moving items from one place to another.

FIND YOUR PERFECT LAYOUT

Finding your ideal shop layout takes some thought and experimentation.

But once you do, your time in the shop will be WAY more efficient — and a lot more satisfying.

Make sure to download our free shop layout tool to help you figure out the best way to layout your tools…

And if you need more storage, check out these plans for three different versions of shop cabinets — including floor and wall mounted versions.

Got any of your own shop layout tips? Share ‘em in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

9 comments

C Holman

I just doubled the size of my shop when we built my husband his own studio. Acquired a small jointer and have my eye on a sliding miter saw. I need to organize everything. This article will be very helpful. Thanks!

I just doubled the size of my shop when we built my husband his own studio. Acquired a small jointer and have my eye on a sliding miter saw. I need to organize everything. This article will be very helpful. Thanks!

sami

ss

ss

Mitch

I work out of my 2 car garage and my wife likes to park in there in the winter so its condensed into the 1 stall except when I’m working. I have a cabinet saw, 13" planer, 2hp dust collector, wide belt sander, assembly/outfeed table, and a 36×48″ bed size laser. the key is everything needs to be on wheels and everything needs to be multifunctional. My assembly/outfeed table has 2 rolls of resin paper (1 for oils, the other for latex paints) and a roll of kraft packing paper mounted to it. I can store my pancake compressor under there and my 3 air nailers and 2 screw guns have a rack they easily slide in and out of. It has shelves that hold my cut to size plywood for the laser. The table saw has a router table on the wing. I store junk on top of the laser where it goes to die. I guess that’s my chaos table.

I work out of my 2 car garage and my wife likes to park in there in the winter so its condensed into the 1 stall except when I’m working. I have a cabinet saw, 13" planer, 2hp dust collector, wide belt sander, assembly/outfeed table, and a 36×48″ bed size laser. the key is everything needs to be on wheels and everything needs to be multifunctional. My assembly/outfeed table has 2 rolls of resin paper (1 for oils, the other for latex paints) and a roll of kraft packing paper mounted to it. I can store my pancake compressor under there and my 3 air nailers and 2 screw guns have a rack they easily slide in and out of. It has shelves that hold my cut to size plywood for the laser. The table saw has a router table on the wing. I store junk on top of the laser where it goes to die. I guess that’s my chaos table.

Walter

I used retractable casters on my workbench, band saw stand and jointer stand. Step on the pedals and the caster is down, allowing me to move the equipment around as needed. Lift the pedal and the equipment is rock solid on it’s legs. I found mine at Lee Valley.

I used retractable casters on my workbench, band saw stand and jointer stand. Step on the pedals and the caster is down, allowing me to move the equipment around as needed. Lift the pedal and the equipment is rock solid on it’s legs. I found mine at Lee Valley.

David Hunter

My shop is a largish garage and I have everything on lockable H/D castors I have also have higher adjusters on each leg because of the uneven floor, works like a dream. to see me waltzing around the shop would prompt you to put it to music.

As usual a great article, love your input to the the wonderful world of woodwork.

My shop is a largish garage and I have everything on lockable H/D castors I have also have higher adjusters on each leg because of the uneven floor, works like a dream. to see me waltzing around the shop would prompt you to put it to music.

As usual a great article, love your input to the the wonderful world of woodwork.

Scott

My shop is 12×14. I first got serious about woodworking as a retirement hobby and over those few years I have reorganized my layout several times. Each time I rearranged it, I became more efficient (fewer steps).

I have made a large workbench at first, but recently built a “hand planing table” that is smaller and lower.

I have learned very much from several online woodworkers and am grateful for their shared experience.BUT, until I actually started working REGULARLY in my shop I didn’t realize how rearranging tools and workspace could improve my enjoyment and efficiency. Nearly all my tables and tools are on casters.

I’ve made a wall for plane storage and hand tools and a separate wall (French cleated) for power tools.

What my wife calls a “mess of tools in a table” I now call my official “CHAOS TABLE”….now I know that I’m not alone in my work technique!

Thanks for all of you from whom I’ve learned so much.

My shop is 12×14. I first got serious about woodworking as a retirement hobby and over those few years I have reorganized my layout several times. Each time I rearranged it, I became more efficient (fewer steps).

I have made a large workbench at first, but recently built a “hand planing table” that is smaller and lower.

I have learned very much from several online woodworkers and am grateful for their shared experience.BUT, until I actually started working REGULARLY in my shop I didn’t realize how rearranging tools and workspace could improve my enjoyment and efficiency. Nearly all my tables and tools are on casters.

I’ve made a wall for plane storage and hand tools and a separate wall (French cleated) for power tools.

What my wife calls a “mess of tools in a table” I now call my official “CHAOS TABLE”….now I know that I’m not alone in my work technique!

Thanks for all of you from whom I’ve learned so much.

Al Steinberg

Chaos TABLE, you say? 8’chaos bench! Haven’t built my cabinets yet.

Chaos TABLE, you say? 8’chaos bench! Haven’t built my cabinets yet.

e caffey

Excellent video and process. Thank you for sharing. I tried to purchase a set of plans from your website and I just gave up it was to many changes for me. Maybe later when your system is less complicated. Keep up the great advise and excellent work. Thank you and good luck in the new shop.

Excellent video and process. Thank you for sharing. I tried to purchase a set of plans from your website and I just gave up it was to many changes for me. Maybe later when your system is less complicated. Keep up the great advise and excellent work. Thank you and good luck in the new shop.

e caffey

Excellent video and process. Thank you for sharing. I tried to purchase a set of plans from your website and I just gave up it was to many changes for me. Maybe later when your system is less complicated. Keep up the great advise and excellent work. Thank you and good luck in the new shop.

Excellent video and process. Thank you for sharing. I tried to purchase a set of plans from your website and I just gave up it was to many changes for me. Maybe later when your system is less complicated. Keep up the great advise and excellent work. Thank you and good luck in the new shop.