CMT Orange Chrome Ripping Blade 10" x T24 FLAT (1/8" Full Kerf)

Choose options

Jonathan's Hot Take Description:

This is one of the top professional full kerf ripping blades on the market for good reason. The carbide teeth are massive, and it’s amazing at removing a lot of material while keeping the cut cool.

When I’m milling a bunch of lumber, this makes quick work of it. Because it has less teeth, it cuts so much cleaner and faster than combo blades for long or repetitive rips. This is easily my most used non-combination blade. As far as the total volume of board foot cutting you'll be doing, ripping is probably #1.

The chrome coating makes it easy to clean, which really extends its life. These new models have 3 additional patents that increase stabilization and keep the blade cooler.

CMT blades are now approved for Sawstop, and if you're looking for a top tier blade at a big box store price, this is definitely the line to go with.

I recommend a full kerf blade for woodworkers who want greater precision, years of sharpenings out of one blade, and have saws with more than 1.5 hp.

I’ve been putting my reputation behind these CMT Chrome blades for a couple years now, and I couldn't be more proud to be carrying them in my store. You’ll absolutely love any blade in this line. I guarantee they’re on par with any high end blade on the market.

Great Resources for Table Saw Blades:

How do I know When My Blade is Dull?

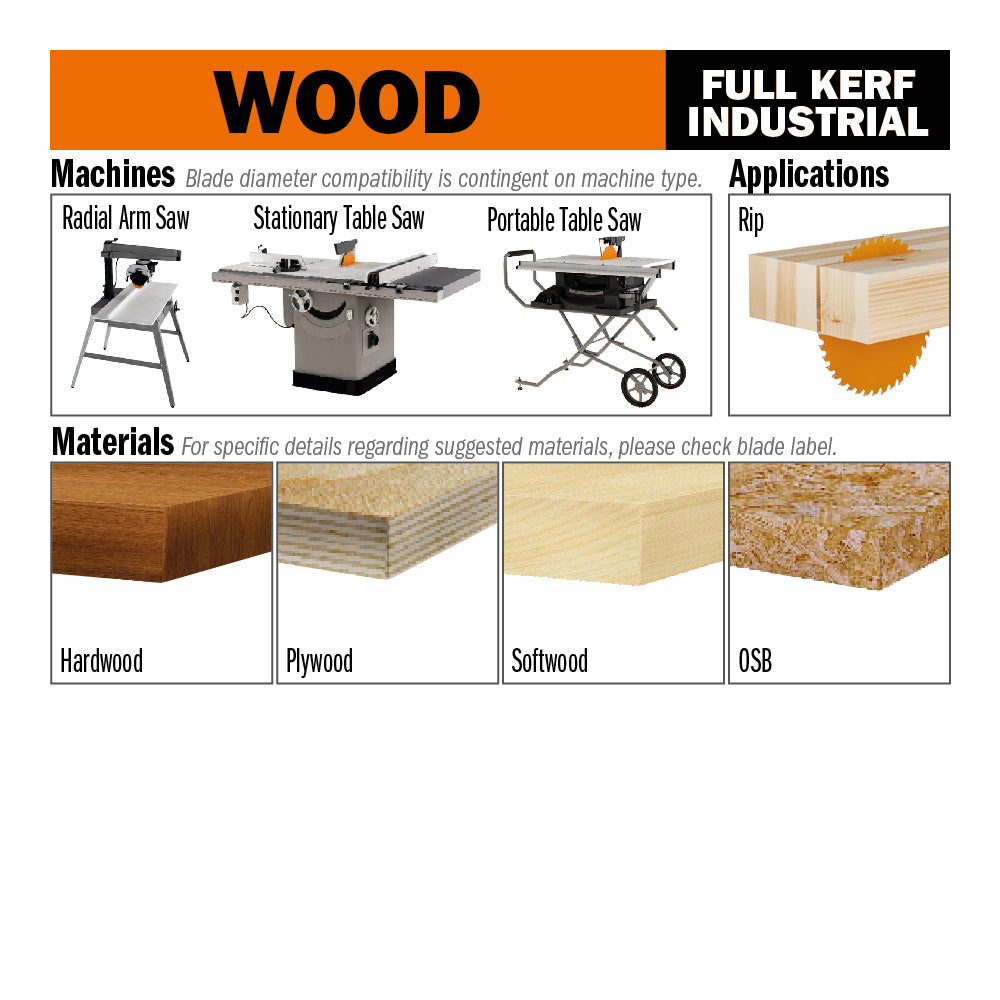

Applications: Ripping Table Saw

Blade Size: 10"

Bore: 5/8"

Tooth Type: FTG

Cutting Angle/Hook Angle: 0°/20°

Full Kerf: .126"

Plate thickness: .087"

Model number: 285.624.10

FTG = Flat top Grind

ATB = Alternate Tooth Bevel

HiATB = High angle Alternate Tooth Bevel

TCG = Trapezoidal or Triple Top Grind (top is flat in the middle and sides are beveled)

RE-SHARPENING INFO Re-Sharpening details are laser engraved on the back of the blade for accurate, full proof, re-sharpening angle information. KEEP YOUR PACKAGING FOR SAFE STORAGE OF YOUR BLADE AND SHIPPING TO SHARPENER. THESE BLADES HAVE EXTRA LARGE, PREMIUM TEETH DESIGNED FOR MULTIPLE SHARPENINGS.

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY- Made with 46-48 HRC precision select high-quality harmonic steel from Germany laser-cut to perfection provides tighter tolerances, longer life and more accurate cuts.

LASER-CUT HEAT EXPANSION SLOTS - Engineered to allow blade expansion when heat build-up occurs from use, preventing blade warping.

TENSIONING - A visible tensioning ring on our blade body is machine and operation tuned for maximum performance providing more stability during the cut. BODY

FLATNESS - Blade body flatness is obtained via a proprietary straightening procedure which delivers substantially reduced tolerances

CHROME PLATED - Chrome plating protects the blade from corrosion, rust, resin and residue build-up, dramatically extending the blade life and making maintenance fast and easy. Plating significantly reduces the motors absorbed power so the blade moves smoothly throughout the cutting operation. Blade plating surface hardness: 380-400 Vickers.

LASER-CUT SLOTS FILLED WITH SOUND-DAMPENING POLYURETHANE Damping polyurethane reduces vibration and noise by 25% compared to standard non-filled saw blades while improving cutting quality and extending blade life. Strategically positioned slots near the toothed crown provide superior vibration isolation and shock absorption. National Noise Emission Standard & Regulations compliant.

CMT XTREME BALANCING* Our patent pending Xtreme Balancing System delivers extremely accurate dynamic blade balancing, which is magnitudes above and beyond what is currently available in the marketplace. Each blade undergoes rigorous assessment and in the event micro-imbalance is detected, appropriate correction holes will be applied. This translates to precise cutting, longer blade life, reduced vibration, lower noise and less wear and tear on your machine components. * TRADEMARK & PAT. PEND.

TEETH:

INDUSTRIAL CHROME CARBIDE Specially formulated chrome carbide ensures cutting teeth stay sharp longer while reducing cutting edge abrasion, improving cut quality and prolonging life.

TRI-METAL BRAZING Our Silver-Copper-Silver Tri-Metal Tooth Brazing handles high stress and heavy impact associated with cutting hard wood and composite material.

PRECISION MIRROR FINISH SHARPENING Each tooth is precision ground on a multi-axis CNC machine which creates perfect edge angles that delivers extra-clean cutting performance and extended life. Featuring less than 0.25 μm Rmax in edge roughness.