Accurate woodworking is all about repeatability. And stop blocks are the Xerox machines of repeatable cuts. (Did I just date myself?)

They ensure precision and consistency in your projects — allowing you to duplicate an operation across multiple boards… and do it fast.

But not all stop blocks are created equal.

In this guide, I’m delving into what makes a stop block truly effective — and the crucial features that elevate it from a tool to a trusted companion.

Whether you're crafting a fine piece of furniture or fashioning intricate joinery, a reliable stop block can be the difference between a masterpiece and a master-disaster.

The block stops here, buddy.

Need a quality stop block? Check out the Katz-Moses No Deflection Stop Block here.

WHAT IS A STOP BLOCK AND HOW DOES IT WORK?

Stop blocks serve as fixed reference points for setting up cuts — and can be used on virtually any stationary tool.

They typically attach to the fence of a tool or sled, acting as a reliable “stopping point” to hold boards at an exact position in relation to the cutter.

Just lock it down on the fence. Butt one end of your workpiece against it. Then make the cut.

Here’s a few ways you can use a stop block for repeatable cuts:

- Cutting chair or table legs to identical lengths on the table saw

- Drilling identically placed holes on multiple boards with a drill press

- Creating a stopped dado or groove in multiple boards on a router table

- Breaking down equal lengths of lumber on a miter saw

- Fashioning consistent joinery

A stop block can be as simple as a block of wood held in place with a clamp.

But more specialized versions include features that really step-up your accuracy and efficiency… which I’ll get into further down.

WHAT ARE THE BENEFITS OF USING A STOP BLOCK?

Repeatability is key to accurate woodworking. If the legs of a table aren’t all the same length, you’re going to have issues.

Stop blocks reduce human error and variability… letting you bake repeatability straight into your workflow.

Think about it.

If you need to cut four table legs to 30”, what method would be faster and more accurate?

- Setting a tape measure on each leg, marking a line at 30”, lining up that mark with your table saw blade, then making the cut

- Locking down a stop block 30” from your table saw blade, butting each leg against it, then making the cuts

In the first method, there are multiple chances for discrepancies. Your 30” mark could be slightly different on each leg. The way you line up each cut could differ. And those discrepancies compound.

With a stop block, you only have to measure one time.

That makes them dependable guides that enhance your precision, repeatability, and efficiency. And that means a better final product.

WHAT TO LOOK FOR IN A QUALITY STOP BLOCK

Multiple factors determine the quality of a stop block and how well it matches your needs.

Here are a few key features to look out for.

ACCURACY AND ZERO DEFLECTION

Deflection happens when a stop block bends or moves a bit when you apply pressure.

This might not seem like a big deal. But in woodworking, even a tiny deflection can lead to imprecise cuts — and those errors get compounded.

Now, here's the thing. Some stop blocks, especially flip-stops, tend to struggle with deflection.

The moving parts of their design introduce a bit of wiggle-room when pressure is applied. And that’s a headache for precision woodworking.

All-in-all, aiming for zero deflection in a stop block is crucial.

It means the stop block stays rock-solid, not budging an inch when you're making those critical cuts. This ensures that your woodworking projects turn out just the way you planned, with clean and precise edges every single time.

DURABILITY

You want a stop block that can withstand the rigors of repeated use without wearing down or becoming less effective.

Especially if you’re a woodworker dedicated to honing your craft over time.

Opt for sturdy materials like extruded aluminum for aftermarket stop blocks, or stable hardwoods and plywood if you plan on making your own.

Durability isn’t just about lasting a long time. It also elevates the overall quality of your woodworking projects, leading to tighter joints and cleaner lines.

SIZE AND DIMENSIONS

The height of a stop block determines which tools and sleds it can work with — so make sure you choose one that matches your needs.

It should reach the base of whatever fence it’s on so you can still use it with thinner stock.

Adjustable height stop blocks have the added advantage of versatility. You can use them on crosscut sleds with short fences, or on other sleds and tool fences where you need to support boards vertically.

COMPATIBILITY AND ATTACHMENT METHODS

Most stop blocks work by attaching into t-track — with the standard size fitting up to 5/16” t-bolts.

T-track is great because it lets you quickly slide your stop block wherever you need it and provides plenty of hold.

But make sure whatever stop block you're considering is compatible with the t-track system you use, or that you have access to a supply of compatible t-track.

Some models might require a specialized track system. It could be great — but make sure all the needed components aren’t going to be cost prohibitive.

VERSATILITY AND ADAPTABILITY

When it comes to stop blocks, versatility is the name of the game.

Here are some key features that make a stop block truly versatile:

- Micro-Adjustment: Micro-adjust mechanisms allow incredibly precise tweaks to your setup, making it easier to dial in super accurate cuts.

- Height Adjustment: A stop block with adjustable height means you can use it with various tools and sleds, accommodating different workpieces with ease.

- Multi-Positioning Capabilities: A versatile stop block should offer multiple points of attachment. This allows you to secure it on the top or face of a fence, giving you flexibility in your setups.

- Flipping Mechanism: This feature lets you quickly move a stop block out of the way without losing its position on the fence. It’s convenient — but deflection is a common issue with these models.

Having a stop block with these features allows you to adapt to different tasks, ensuring precision and efficiency in your projects no matter the complexity.

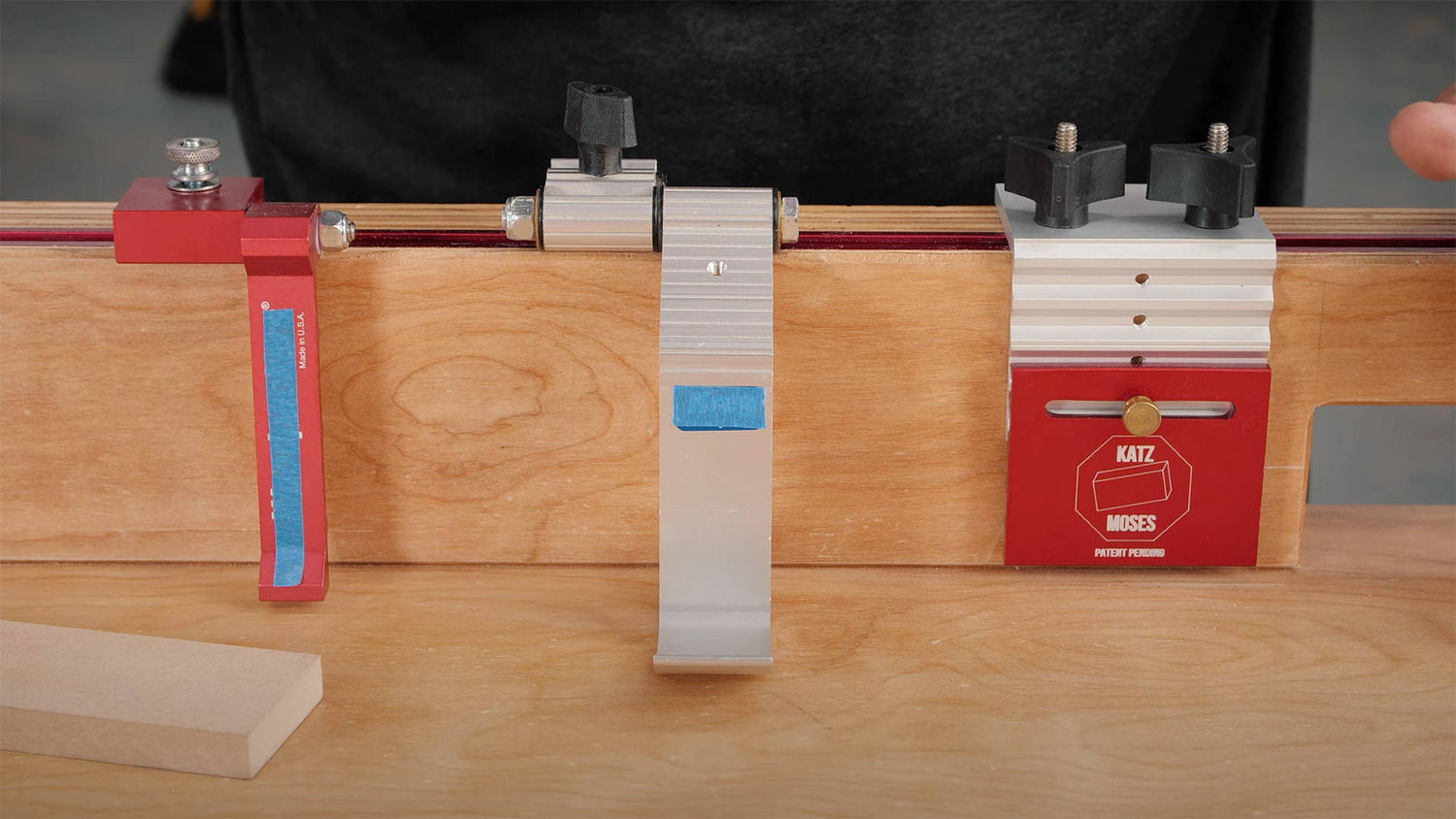

SHAMELESS PLUG: THE KATZ-MOSES NO DEFLECTION STOP BLOCK

Ok, here it is: The Katz-Moses No Deflection Stop Block is the BEST stop block on the market (my mom said so herself).

But seriously, I’m very proud of this tool. And it really is a beast.

- ZERO Deflection: Two locking t-bolts mean it doesn’t budge, even when you smash 8/4 lumber against it. No other stop block I’ve tried can claim the same.

- Adjustable Height: Extends from 2 ¼” to 3 ¾” — with a positive stop every ½” so you can use it on various tool fences and sleds.

- Micro-Adjust: Dial in surgically precise cuts with a full 1” of micro-adjust.

- Versatile Positioning: Attach it to the top or face of your fence, and extend the face up to 1 ½” from the t-bolts for greater versatility and applications.

- Made in the USA: This is a high-quality, homemade product designed, built, and sold by a small business.

I developed this stop block to improve my own woodworking… and it still blows my mind that I get to share it with other woodworkers like you.

Ok. I’ll stop now.

GET A STOP BLOCK THAT ROCKS

A quality stop block is the cornerstone of precise woodworking.

It ensures your cuts are accurate, your joints fit perfectly, and your projects turn out flawlessly.

Now that you understand the elements that make a stop block truly effective — what’s holding you back from getting one for yourself?

Need a good crosscut sled for your stop block? Build this one.

What features do you look for in a stop block? Let us know in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

7 comments

carl d weisdack

cvouple of things i wanted to know is this stop block in stock and ready to ship. also wanted to know the t-track that i want to use is a low profile its 3/10 of a inch thick will your stop block with that thickness. i had placed a order before and had to wait too long to receive the unit and my wife canceled the order. please let me know would like to reorder

thanks carl d weisdack

cvouple of things i wanted to know is this stop block in stock and ready to ship. also wanted to know the t-track that i want to use is a low profile its 3/10 of a inch thick will your stop block with that thickness. i had placed a order before and had to wait too long to receive the unit and my wife canceled the order. please let me know would like to reorder

thanks carl d weisdack

William Fox

I bought this and it works great. However, because it can’t flip out of the way I don’t use it as much as I thought I would. Please consider making a new version with a flip option.

I bought this and it works great. However, because it can’t flip out of the way I don’t use it as much as I thought I would. Please consider making a new version with a flip option.

Roy Thurston

can this stop be made to fit a Rockler table saw sled, is it in stock and how long to get it, I live near Atlanta, GA, thank you

can this stop be made to fit a Rockler table saw sled, is it in stock and how long to get it, I live near Atlanta, GA, thank you

Ron Williams

Will your stop block fit directly on my Rockler fence?

Will your stop block fit directly on my Rockler fence?

J K

Any suggestions on how to attach this stop to the non standard track on the Sawstop Sliding Table?

Any suggestions on how to attach this stop to the non standard track on the Sawstop Sliding Table?

John Maguranis

I’ve made an assortment of jigs over time and it was always frustrating to find a stop block to work. I bought one of yours last year and have to say it’s the best one out there. I’ll be ordering another one soon.

Best,

John

I’ve made an assortment of jigs over time and it was always frustrating to find a stop block to work. I bought one of yours last year and have to say it’s the best one out there. I’ll be ordering another one soon.

Best,

John

Deb

I have this stop and why do I have it.? Because I had the one next to it in the picture.

This is the only one to have accurate and durable.

I have this stop and why do I have it.? Because I had the one next to it in the picture.

This is the only one to have accurate and durable.