To get precise cuts on your bandsaw, you need to make sure the table plays nice with the blade.

And that means occasionally checking for squareness.

You can of course just use a regular square (as long as it’s short enough to fit under the bandsaw blade guides — like this 3” magnetic speed square).

But my favorite method involves a nifty little test that shows squareness in real-time and with real cuts.

All you need is an offcut of wood with square and parallel edges (a 2x4 works great).

Here’s what to do.

1. MAKE A NON-THROUGH CUT

Set the offcut on its edge so the wider faces stand vertically.

Turn on the bandsaw and carefully cut into the board, stopping once the blade is fully embedded. Then pull the board away from the blade.

Make sure to keep the bottom edge flat on the table as you cut — and don’t cut all the way through.

2. FLIP THE BOARD UPSIDE DOWN

Once you've done the non-through cut, flip the offcut onto its opposite edge.

The faces will still stand vertically. But the original “bottom” edge is now facing up.

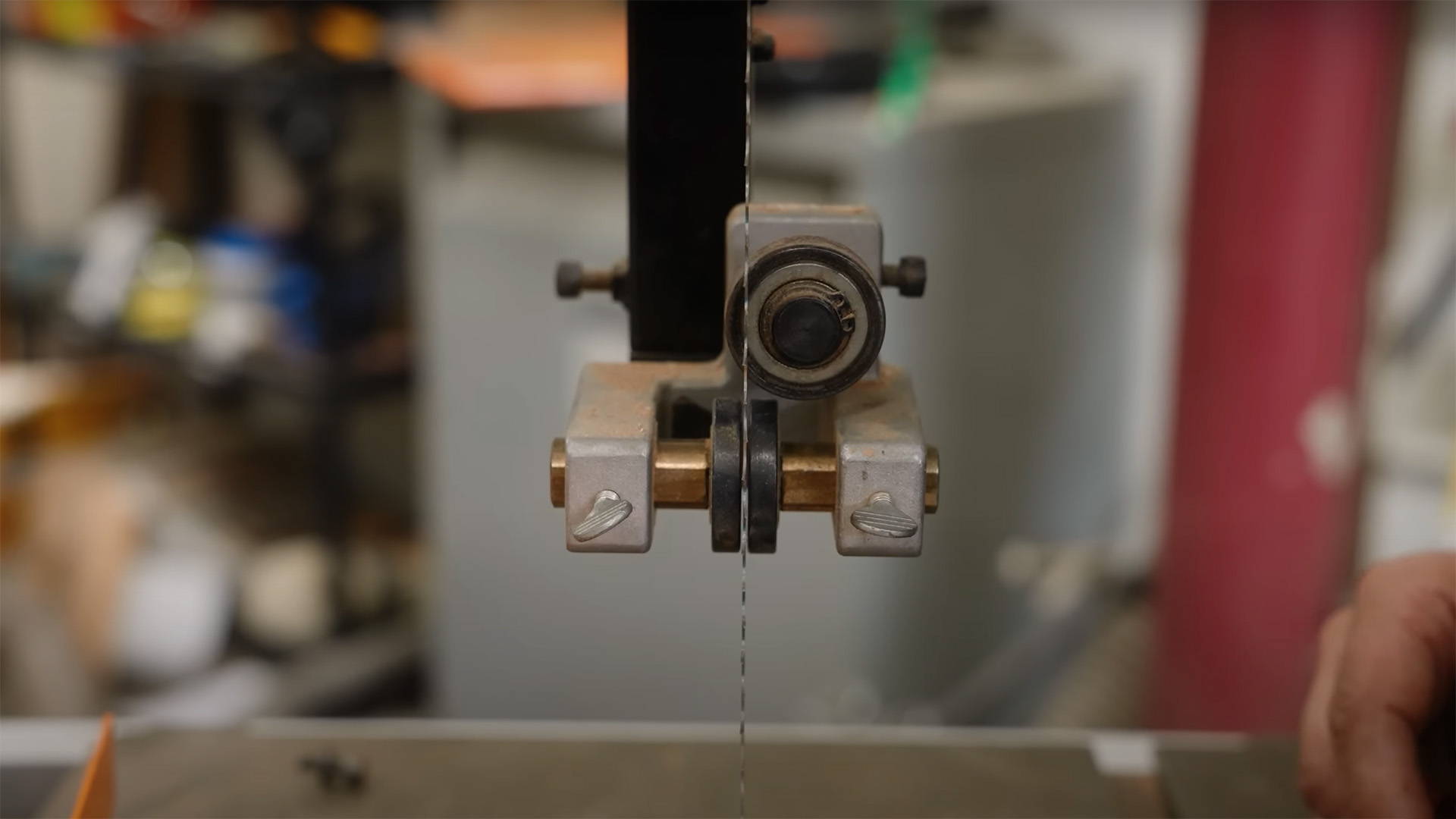

3. SLIDE THE KERF OVER THE BACK OF THE BLADE

Bring the board around to the back of the bandsaw blade.

Now gently try to slide the back of the bandsaw blade into the kerf-cut you made before.

It should slide in like a puzzle piece, without causing any flexing or deflection of the blade.

If the blade slides smoothly into the groove, your bandsaw blade and table are square to each other.

If the blade isn't groove-friendly, adjust the table angle as needed.

Fit the kerf around the blade, adjust the bandsaw table until the board's bottom edge sits flat, and test again as necessary.

Throw this test into your bandsaw routine every now and then as a quality check to keep your cuts on point.

It’ll keep your cuts sharp and square. Because the details matter, my friend!

Want to check if your square is actually square? Here’s a way to test.

What’s your preferred method for squaring a bandsaw table and blade? Let us know in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

7 comments

Anonymous

https://www.wwgoa.com/video/is-your-bandsaw-square-031177

https://www.wwgoa.com/video/is-your-bandsaw-square-031177

Anonymous

@ Kevin I think @Roger meant “kerf” but was foiled by autocorrect changing the word to “here”.

@ Kevin I think @Roger meant “kerf” but was foiled by autocorrect changing the word to “here”.

Anonymous

I was wrong on my first comment. A flip and a turn will not cancel out the error. Still, it’s better to leave the original edge down, as others have said.

I was wrong on my first comment. A flip and a turn will not cancel out the error. Still, it’s better to leave the original edge down, as others have said.

Kevin

@Patrick, 2×4′s are generally parallel on short offcuts. With that in mind, this should be a fairly good indicator of how square the blade is to the table. If there is doubt of parallelism then run the “offcut” through a planer or the table saw to make the edges parallel.

@Roger. I dont know what “here” i supposed to mean so it’s difficult to determine what Roger’s method accomplishes.

@Steve, actually the way it is instructed will accomplish the needed results. Steve method would work only if the cut is a through cut. A through cut would be ok if a thin enough offcut was used. Say 1-1/2 the width of the blade.

@Patrick, 2×4′s are generally parallel on short offcuts. With that in mind, this should be a fairly good indicator of how square the blade is to the table. If there is doubt of parallelism then run the “offcut” through a planer or the table saw to make the edges parallel.

@Roger. I dont know what “here” i supposed to mean so it’s difficult to determine what Roger’s method accomplishes.

@Steve, actually the way it is instructed will accomplish the needed results. Steve method would work only if the cut is a through cut. A through cut would be ok if a thin enough offcut was used. Say 1-1/2 the width of the blade.

Anonymous

Actually, flipping the board upside down and using the back of the blade is completely wrong. Doing so cancels out any error in perpendicularity™, and the cut will always line up with the blade, no matter what angle the table is.

Leave the same edge down, then spin the cut around to the back edge of the blade, and any amount of non-perpendicularity™ will be doubled.

Actually, flipping the board upside down and using the back of the blade is completely wrong. Doing so cancels out any error in perpendicularity™, and the cut will always line up with the blade, no matter what angle the table is.

Leave the same edge down, then spin the cut around to the back edge of the blade, and any amount of non-perpendicularity™ will be doubled.

Patrick

I agree with Roger. Flipping the board introduces the possibility of inaccurate results. Keeping the bottom of the board always down means the shape of the top edge does not matter. Ignoring this little thing though this is a great way to confirm the squareness of the bed to the blade!

I agree with Roger. Flipping the board introduces the possibility of inaccurate results. Keeping the bottom of the board always down means the shape of the top edge does not matter. Ignoring this little thing though this is a great way to confirm the squareness of the bed to the blade!

Roger Gladding

That method relies on the wood sides being parallel. If you cut the here then keep the same bottom face on the bed and turn it around it should let the blade into the here from the back.

That method relies on the wood sides being parallel. If you cut the here then keep the same bottom face on the bed and turn it around it should let the blade into the here from the back.