The less you measure in woodworking, the better.

And smart woodworkers know how to let their tools do the measuring for them.

This is especially true when you need a perfectly centered mortise.

Today, I’m showing you how to cut a centered mortise with a plunge-base router — and no measuring.

This is a great technique that can be adapted to a ton of other tools…

Including your drill press (another great way to cut mortises).

1. SELECT YOUR BIT

First up, pick your bit.

A regular spiral bit will do the trick, but an upcut bit cuts the fastest.

Just make sure the edges of your mortise will be hidden (they can get a little gnawed up).

If you’re looking for cleaner edges, go for a compression or down-cut bit.

Bit diameter depends on the width of your mortise… but it’s not ultra critical for this technique.

2. SET THE EDGE GUIDE

Now, set the edge guide on your router (or 3x3 Custom Trim Router Jig).

Adjust it so that the edge of the bit furthest from the edge guide is roughly where you want the outside edge of your mortise to be.

This doesn’t need to be super precise. Eyeballing is plenty.

3. SET SOME END STOPS

It’s optional, but setting end stops makes the process easier and more accurate.

They help keep your mortise length consistent — with no chance of going past your line.

A simple clamp can work as your stop, or even a scrap piece attached with double stick tape.

Just set one up to stop your router at the right place at each end of the mortise.

4. MAKE THE FIRST PASS

Keeping the edge guide flush against your workpiece, plunge the bit and make your first pass.

Cut the full length of this side of your mortise — but don’t try to go too deep all at once.

You’ll get to your final mortise depth over multiple passes.

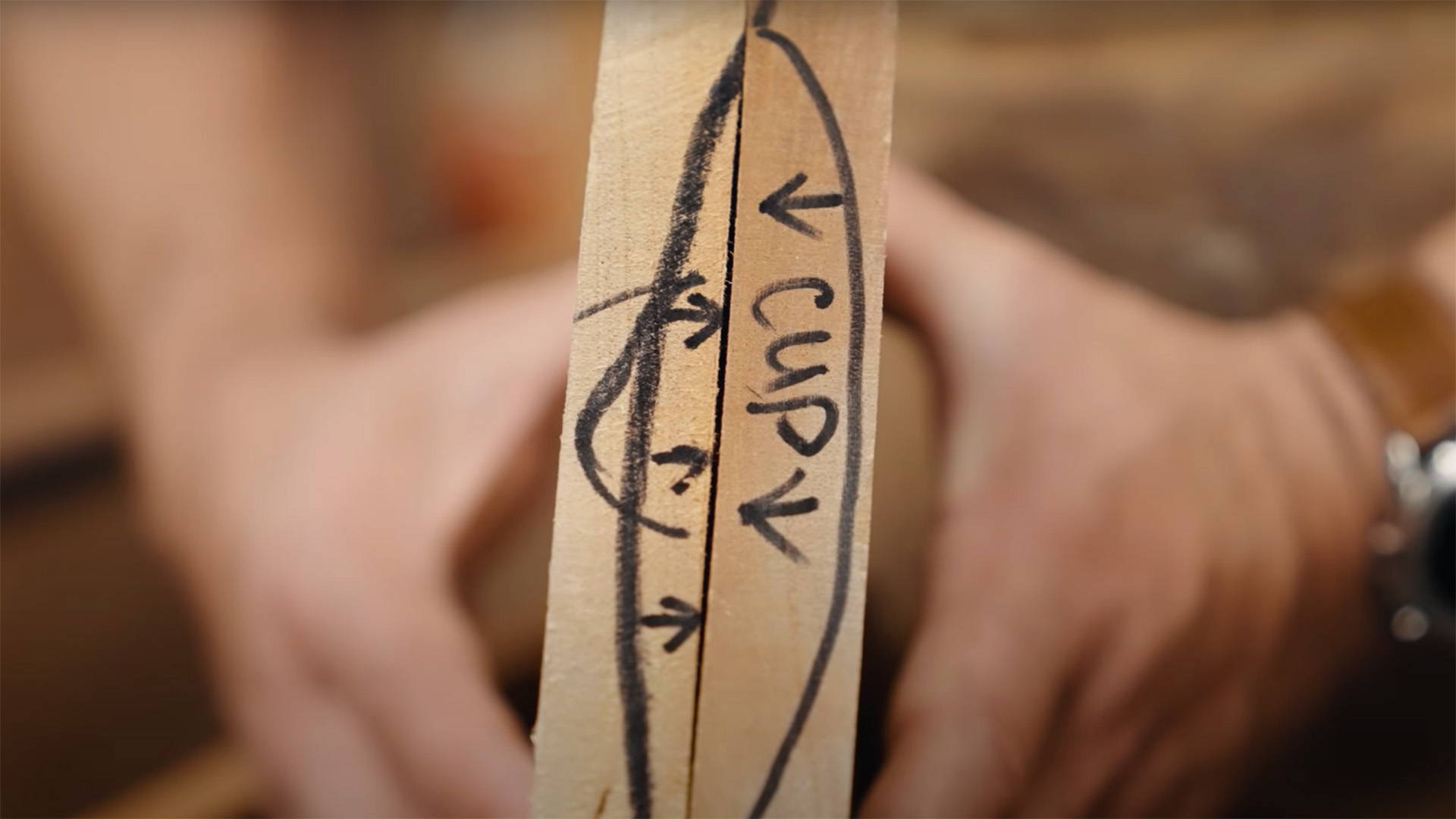

5. CUT THE OPPOSITE EDGE

Without adjusting the edge guide, route the other side of the mortise.

The 2 cuts will combine into a larger, perfectly centered one.

Now it’s just a matter of getting to your final depth.

6. ALTERNATE AND REPEAT

Keep alternating sides, routing a little deeper each time.

Once you’re at your final mortise depth, it’s time for a little clean up.

7. SQUARE UP THE CORNERS WITH A CHISEL

Grab a chisel and square up those round corners.

My favorite technique is to sit the back of the blade flat against one end of the mortise and “swivel” down into the corner.

You can read more chisel tips here.

And there you have it.

A simple, repeatable, and perfectly centered mortise — without having to worry about measuring.

Want to learn more about cutting a mortise and tenon joint? Read this.

What’s your secret for centered mortises? Let us know in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

7 comments

Brian

I really like the 3×3 Custom floating tenon jig. It makes for awesome repeatability and infinite adjustments. Check out Tamar’s YouTube on the build and she’s got plans on her site too. I’ve always been a fixed tenon guy, but floating tenon are great since the two mating mortises can be done with the same setup and then you can dial in a perfect fit by milling up the tenon for a snug fit. I recently built a nice quilt case for my wife and the case joinery with floating tenons was perfect. And the best part, I didn’t invest in an expensive dominio rig.

I really like the 3×3 Custom floating tenon jig. It makes for awesome repeatability and infinite adjustments. Check out Tamar’s YouTube on the build and she’s got plans on her site too. I’ve always been a fixed tenon guy, but floating tenon are great since the two mating mortises can be done with the same setup and then you can dial in a perfect fit by milling up the tenon for a snug fit. I recently built a nice quilt case for my wife and the case joinery with floating tenons was perfect. And the best part, I didn’t invest in an expensive dominio rig.

Larry Adams

My name is Larry Adams, online editor with Woodworking Network. I saw a blog post that I would like to pick up for our upcoming Red Book edition and was hoping to get your approval for its use. You would get a byline as well as contact information in the story. In addition to email, I can be reached at 773-951-6564.

My name is Larry Adams, online editor with Woodworking Network. I saw a blog post that I would like to pick up for our upcoming Red Book edition and was hoping to get your approval for its use. You would get a byline as well as contact information in the story. In addition to email, I can be reached at 773-951-6564.

David Gordon

I liked the “Centred mortice description”, clear and simple.

I liked the “Centred mortice description”, clear and simple.

John N

@Tal – You set your marking gauge to “half of the rest of it.”

Measure and mark the tenon width from the edge in some fashion, like setting your marking gauge to a specific distance, or lining up a chisel (or the tenon if you already cut it!) flush from the edge. Make a little nick, if it’ll be hidden by the tenon shoulder, or a sharp pencil dot if not.

Use a divider to set the half-distance. Set it in the nick or on the dot, and twiddle the length until you’re right on the edge after two twists (not a great description, see youtube if needed.) If you want to be ultra precise, lay your square down so it crosses the point, then lay your divider tips right next to it to ensure you’re not dividing a miter line instead.

Match your marking gauge to the divider length, and boom!

@Tal – You set your marking gauge to “half of the rest of it.”

Measure and mark the tenon width from the edge in some fashion, like setting your marking gauge to a specific distance, or lining up a chisel (or the tenon if you already cut it!) flush from the edge. Make a little nick, if it’ll be hidden by the tenon shoulder, or a sharp pencil dot if not.

Use a divider to set the half-distance. Set it in the nick or on the dot, and twiddle the length until you’re right on the edge after two twists (not a great description, see youtube if needed.) If you want to be ultra precise, lay your square down so it crosses the point, then lay your divider tips right next to it to ensure you’re not dividing a miter line instead.

Match your marking gauge to the divider length, and boom!

John N

@Other John – You can do this exact same trick with a marking gauge, since it just relies on referencing the outer edges (think of it like bracketing the imaginary center line.)

If your opposite face is too rough to reference: 1, the center line will be equally rough, but find a good place anyway and press the cutter in just enough to find again, flip back to the good side, and adjust the gauge to fit back in it. You bracket the edges the same way, and just reference the same face twice to slice the line.

To get the tenon centered, mark it the exact same way: same distance from either side,or two different distances for the same side. Ideally without changing the setting, but you can also set it to the face-mortise edge distance pretty reliably.

@Other John – You can do this exact same trick with a marking gauge, since it just relies on referencing the outer edges (think of it like bracketing the imaginary center line.)

If your opposite face is too rough to reference: 1, the center line will be equally rough, but find a good place anyway and press the cutter in just enough to find again, flip back to the good side, and adjust the gauge to fit back in it. You bracket the edges the same way, and just reference the same face twice to slice the line.

To get the tenon centered, mark it the exact same way: same distance from either side,or two different distances for the same side. Ideally without changing the setting, but you can also set it to the face-mortise edge distance pretty reliably.

Taliaferro

Could you explain more how you establish the mortise width that you need. For example, your method provides a perfectly centered mortise. The mortise width appears to be based on laying out your first cut line an exact distance from the center line. For example, if you want a 4mm mortise, the one edge must be exactly 2mm from centerline.

Thanks

Could you explain more how you establish the mortise width that you need. For example, your method provides a perfectly centered mortise. The mortise width appears to be based on laying out your first cut line an exact distance from the center line. For example, if you want a 4mm mortise, the one edge must be exactly 2mm from centerline.

Thanks

John

Well heck, I was hoping for hand tool tips on this.

I’m in the middle of building a small built-in cabinet and my mortises and tenons are pretty iffy to be charitable. Be nice to be able to nail centers.

Part of it is just a lack of practice, of course. I’ve got a lot more to do and none will be visible in the finished product, so I should be better by the end.

Well heck, I was hoping for hand tool tips on this.

I’m in the middle of building a small built-in cabinet and my mortises and tenons are pretty iffy to be charitable. Be nice to be able to nail centers.

Part of it is just a lack of practice, of course. I’ve got a lot more to do and none will be visible in the finished product, so I should be better by the end.