Wood glue makes boards slide against each other like Bowser on a banana peel — and that’s a problem when you’re trying to keep them aligned.

But there’s an easy way to add some friction…

So you can keep boards in position and avoid a panic realignment after you tighten down your clamps.

All it takes? A bit of sandpaper — or some table salt.

Before clamping the boards together, rub a piece of sandpaper against itself above the glue you spread.

Make sure you rub the rough face of the sandpaper together. The granules will break off and scatter across the glue.

Even a little bit creates enough friction to keep the boards from sliding against each other as you tighten your clamps.

And since the granules are small, they’ll compress between the boards and won’t leave any gaps in the joint.

Feeling salty? You can do the same thing with fine table salt.

Sprinkle a bit over the glue-covered face or edge and you’re good to go.

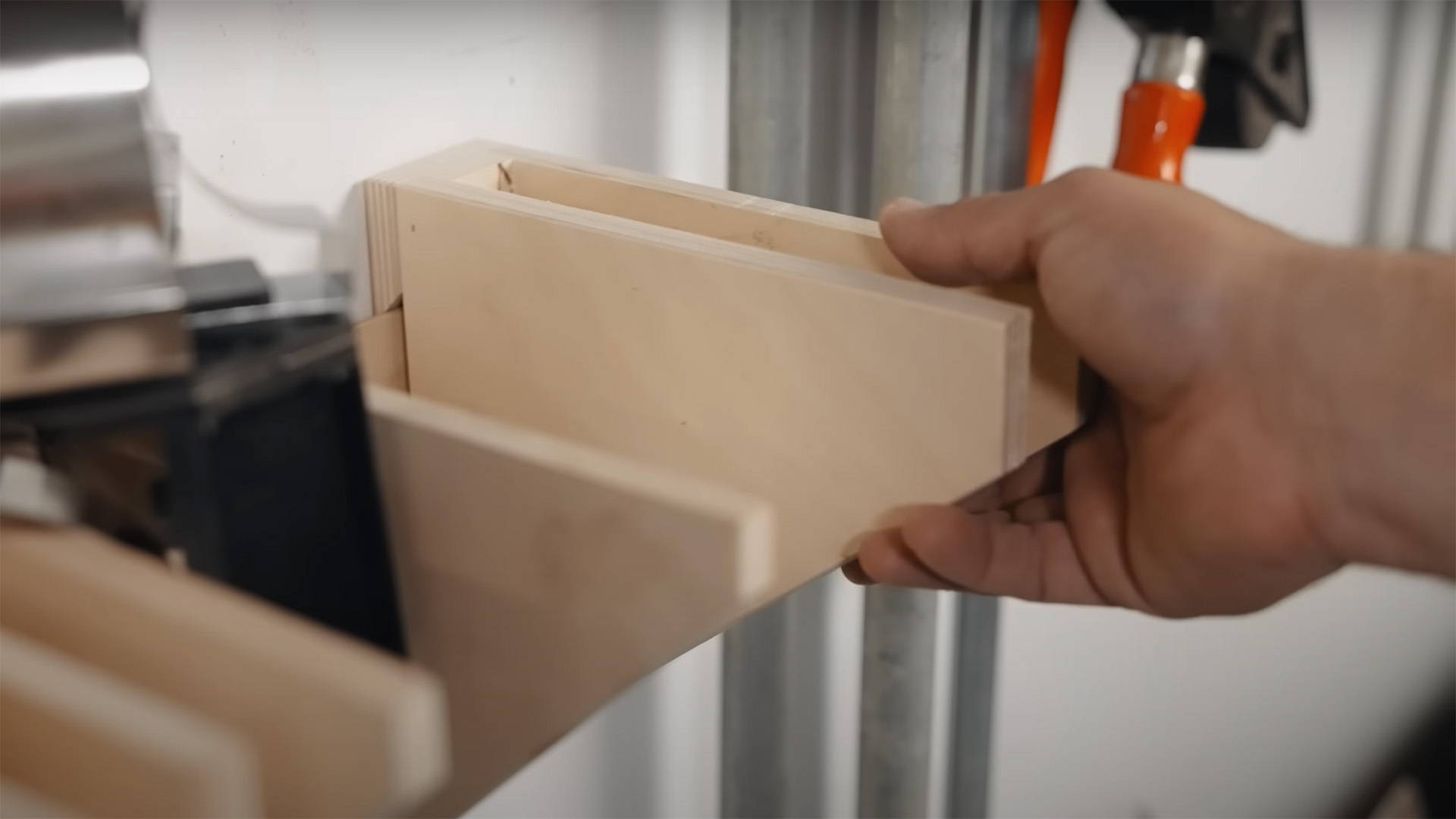

This is a great tip for when you're gluing boards together at their edges or faces…

And can really take some of the stress out of glue ups.

Want to learn tips for better panel glue ups? Read this.

How do you keep boards aligned during glue ups? Let us know in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

7 comments

Lawrence Barr

As noted, salt affects glue strength (it dissolves & reacts chemically)

I have a different solution. Prior to clamping, I position the glued piece using a pin nailer. I use a block of wood to raise the nailer so that ~ 1/2" of the pin remains proud. After clamping & drying, pull the pins out using a vise grip + a 1/2" thick piece of wood as a fulccrum. The grabbed portion of the pin often breaks off, but the pin remains accessible for another bite. I size the pin between 1/4 -3/8" into the base wood (1/2" + thickness of attached piece + 1/4-3/8"). Works well for soft wood – not sure for hardwood. If only gentle sanding after glueing, adjust the nailer to push the pin below the surface & leave in place.

As noted, salt affects glue strength (it dissolves & reacts chemically)

I have a different solution. Prior to clamping, I position the glued piece using a pin nailer. I use a block of wood to raise the nailer so that ~ 1/2" of the pin remains proud. After clamping & drying, pull the pins out using a vise grip + a 1/2" thick piece of wood as a fulccrum. The grabbed portion of the pin often breaks off, but the pin remains accessible for another bite. I size the pin between 1/4 -3/8" into the base wood (1/2" + thickness of attached piece + 1/4-3/8"). Works well for soft wood – not sure for hardwood. If only gentle sanding after glueing, adjust the nailer to push the pin below the surface & leave in place.

OleCuss

The salt idea has been addressed. It does adversely affect the adhesive bond.

The grit should work pretty well but it is not going to be finely directed so in some joints you may have grit almost at the surface. So if you then need to plane things down you may be running a blade into bits of grit.

Another idea is to lay one or two brads into the joint. The downsides are few because you can control their distance from any surfaces which might later be milled. But things can get just a little weird while you are trying to compress the brads into the joint. But you can actually hammer the brads most of the way into the surface to be glued and then snip the head off just a little above the wood leaving a fairly sharp top to a brad nearly fully embedded in one piece of wood and then press the other piece of wood into place pretty securely.

Alternatively? Yup, dowels, dominoes. Most of us can do those fairly quickly but it does take a bit of time to get things really precise.

The salt idea has been addressed. It does adversely affect the adhesive bond.

The grit should work pretty well but it is not going to be finely directed so in some joints you may have grit almost at the surface. So if you then need to plane things down you may be running a blade into bits of grit.

Another idea is to lay one or two brads into the joint. The downsides are few because you can control their distance from any surfaces which might later be milled. But things can get just a little weird while you are trying to compress the brads into the joint. But you can actually hammer the brads most of the way into the surface to be glued and then snip the head off just a little above the wood leaving a fairly sharp top to a brad nearly fully embedded in one piece of wood and then press the other piece of wood into place pretty securely.

Alternatively? Yup, dowels, dominoes. Most of us can do those fairly quickly but it does take a bit of time to get things really precise.

Anonymous

After seeing Suman’s evaluation on YouTube:

https://youtu.be/QfTsHJqykMs?t=217

I’m going to take Jonathan’s no-slip glue-up suggestions with a grain of salt.

Yeah, pun intended.

After seeing Suman’s evaluation on YouTube:

https://youtu.be/QfTsHJqykMs?t=217

I’m going to take Jonathan’s no-slip glue-up suggestions with a grain of salt.

Yeah, pun intended.

Scott Sehlhorst

A pinch of sawdust sprinkled in the glue-up has worked for me. Gets the same mechanical effect without introducing foreign materials which could undermine the strength

A pinch of sawdust sprinkled in the glue-up has worked for me. Gets the same mechanical effect without introducing foreign materials which could undermine the strength

Larry

A youtuber just tested the salt thing out and it does work (keep from sliding) but more important it reduce the strength of the glue joint!

A youtuber just tested the salt thing out and it does work (keep from sliding) but more important it reduce the strength of the glue joint!

D. Thomas Lamourine

Have you watched Suman’s video on “woodworking myths”. he shows rather clearly that the salt in the glue isn’t such a great idea as it reacts/melts/crystalizes in the liquid of the glue and weaken the joint!

Have you watched Suman’s video on “woodworking myths”. he shows rather clearly that the salt in the glue isn’t such a great idea as it reacts/melts/crystalizes in the liquid of the glue and weaken the joint!

Neil Relph

On big glue-ups I sometimes use a few dots of superglue to keep the boards aligned whilst they’re clamped and the “PVA” can do it’s stuff

On big glue-ups I sometimes use a few dots of superglue to keep the boards aligned whilst they’re clamped and the “PVA” can do it’s stuff