If your woodworking square isn’t square, your projects won’t be either.

It might show as sloppy cuts that aren’t 90°, joinery that’s far from fitting, or a growing ball of rage in the pit of your stomach.

Now, as I always like to say, “woodworking is NOT machining.” You can still get great results with bigger tolerances.

But if you suspect your square is sabotaging your projects, here’s an easy way to test its accuracy.

Use it for your combination squares, t-squares, machinist squares, or any other highly-sus layout tool.

WHAT YOU'LL NEED

- Your square

- A pencil or a marking knife (I prefer the latter)

- A straight-edged board (like plywood or a jointed piece of hardwood)

THE SQUARE SQUARENESS TEST

1. GET YOUR BOARD READY

Start with a board that has a known straight edge.

It could be plywood or a jointed piece of hardwood. This board will be your reference.

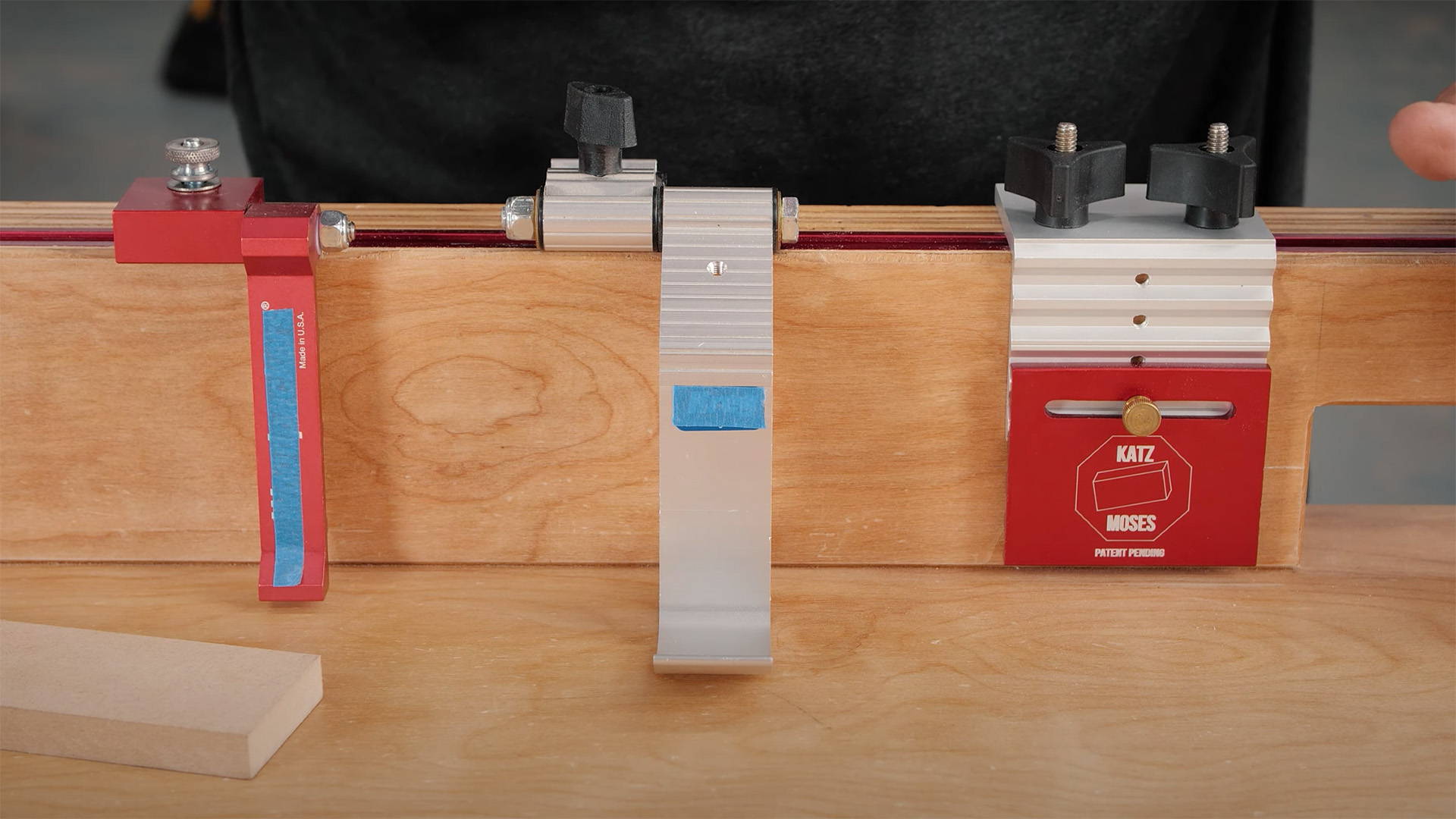

2. POSITION YOUR SQUARE

Put the square's fence flat against the board's edge. Make sure the blade is flat on the board's face.

Pay attention to whether the fence is pointing to your left or right.

3. MARK THE FIRST LINE

Press the square's fence firmly against the board, then mark a clear line along the edge of the square's blade.

I prefer a marking knife because the thinner line lets you see discrepancies more clearly in the next step.

4. FLIP THE SQUARE AND MARK A SECOND LINE

Flip the square so the fence points the opposite direction from before. If it was pointing to the left, flip it so it’s pointing to the right.

Adjust it so the square's blade is right next to the first line you made, hold the fence firmly against the board’s edge, and mark a second line.

Make sure you reference your marking knife or pencil off the same side of the blade!

5. CHECK THE LINES

Now inspect the two lines you marked. They should be perfectly parallel, with an even gap between them along their entire length

If they are, your square is all set for precise woodworking. Get to it!

WHAT IF YOUR SQUARE ISN’T SQUARE?

If the lines you marked aren’t parallel, try the test again to be sure.

And for squares with sliding blades, make sure the thumb screw is fully tightened down.

But if none of that works, you could potentially try grinding the blade or fence back into square. This is a little risky — and could potentially lead to more problems…

So at that point it might be best to invest in a new square.

Want more precise cuts and tighter fitting joinery? Here are my top tips for accurate woodworking.

Ever struggled with a wonky square? Let us know how you dealt with it in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

8 comments

Rob

I’ve been struggling with this problem for weeks. I own multiple trisquares, engineering squares and combination squares. I’m butterfingered to a comic degree. Every time I purchase something I know to be certified square I drop it within 48 hours of acquisition. I’m beginning to lose hope of ever making right joints.

I’ve been struggling with this problem for weeks. I own multiple trisquares, engineering squares and combination squares. I’m butterfingered to a comic degree. Every time I purchase something I know to be certified square I drop it within 48 hours of acquisition. I’m beginning to lose hope of ever making right joints.

Craig

I spent months trying to get my miter saw squared up and even though the blade seemed square to the fence the cuts were always visibly out of square.

I finally decided to check to see if my square was indeed square. It wasn’t even close. The good news is my other squares are fine and the saw is now squared up correctly.

I spent months trying to get my miter saw squared up and even though the blade seemed square to the fence the cuts were always visibly out of square.

I finally decided to check to see if my square was indeed square. It wasn’t even close. The good news is my other squares are fine and the saw is now squared up correctly.

Robert Bamford

For Scott: works off the same edge. The square is flipped “horizontally”, so it registers in the same edge.

For Scott: works off the same edge. The square is flipped “horizontally”, so it registers in the same edge.

Scott

The method described above still relies on both top and bottom edges of the lumber being perfectly parallel. Maybe this is a safe assumption? What if you used the square to actually draw a square? This is gonna sound more complicated than it is but try it and it’ll make sense. Draw a line along both edges of your square to create sides 1 and 2, but make sure the line for the first side starts exactly at the far edge/end of your square. Rotate square 90 and align one edge to the side 2 you just drew and draw side 3 using other edge. Rotate square again and repeat last step but before drawing that 4th side you must align the end edge of your square with the edge you drew of side 2. If the 4th side you just drew doesn’t cross perfectly at the start point of the line for side 1, you’re square is out of true.

The method described above still relies on both top and bottom edges of the lumber being perfectly parallel. Maybe this is a safe assumption? What if you used the square to actually draw a square? This is gonna sound more complicated than it is but try it and it’ll make sense. Draw a line along both edges of your square to create sides 1 and 2, but make sure the line for the first side starts exactly at the far edge/end of your square. Rotate square 90 and align one edge to the side 2 you just drew and draw side 3 using other edge. Rotate square again and repeat last step but before drawing that 4th side you must align the end edge of your square with the edge you drew of side 2. If the 4th side you just drew doesn’t cross perfectly at the start point of the line for side 1, you’re square is out of true.

Don

One important clarification to my previous post re dimpling a square. This ONLY works for standard FRAMING SQUARES where tongue and body are in the same plane !! Don’t try it with your combination squares or speed squares!!

One important clarification to my previous post re dimpling a square. This ONLY works for standard FRAMING SQUARES where tongue and body are in the same plane !! Don’t try it with your combination squares or speed squares!!

Don

Actually the ball peen approach suggested is not correct. Although using a ball peen with a center punch would be a workable combination. Figure out which direction the blades – tongue and body -must move to get into square. If they must move apart – center punch a dimple on the inside apex. Check again. If ok now – you are set. If not give it another whack/dimple. And so on…until you are happy with the squareness.

If the tongue and body need to come together to be square – repeat the process – only this time dimpling towards the outside corner of the square. And so on.

I have an old square that took 4 dimples to pull it into square… far cheaper than taking it to a machine shop!!

It doesn’t take much to knock the square out of whack. Dropping from a bench top seems minor – but it can cause a problem. Dimpling doesn’t seem like much either but it will bring the square back into square with a couple of whacks. [both ball peen and claw hammer will work with the center punch. :) ]

Actually the ball peen approach suggested is not correct. Although using a ball peen with a center punch would be a workable combination. Figure out which direction the blades – tongue and body -must move to get into square. If they must move apart – center punch a dimple on the inside apex. Check again. If ok now – you are set. If not give it another whack/dimple. And so on…until you are happy with the squareness.

If the tongue and body need to come together to be square – repeat the process – only this time dimpling towards the outside corner of the square. And so on.

I have an old square that took 4 dimples to pull it into square… far cheaper than taking it to a machine shop!!

It doesn’t take much to knock the square out of whack. Dropping from a bench top seems minor – but it can cause a problem. Dimpling doesn’t seem like much either but it will bring the square back into square with a couple of whacks. [both ball peen and claw hammer will work with the center punch. :) ]

Doug

Hi fellow dust lovers,

I have my grandfather’s large, old framing square. Its edges were quite rounded and no longer square.

I contacted a local machine shop and they agreed to give it new edges, perfectly square. Since I was going to do that, I bought a new aluminum square ($20) and had them both done. It was $100 but worth it to me because #1 it was grandpas and #2 it is as perfectly square and straight as I could hope for.

It may seem pricey until compared to other high-end brands.

Doug

Hi fellow dust lovers,

I have my grandfather’s large, old framing square. Its edges were quite rounded and no longer square.

I contacted a local machine shop and they agreed to give it new edges, perfectly square. Since I was going to do that, I bought a new aluminum square ($20) and had them both done. It was $100 but worth it to me because #1 it was grandpas and #2 it is as perfectly square and straight as I could hope for.

It may seem pricey until compared to other high-end brands.

Doug

Steven Hunter

Flat framing style squares can be tuned with a ball peen hammer. I’m sure there are you tube videos how to do it. I always regularly check my squares, especially if they’ve been dropped.

Flat framing style squares can be tuned with a ball peen hammer. I’m sure there are you tube videos how to do it. I always regularly check my squares, especially if they’ve been dropped.