T-track is one of the best pieces of hardware for souping up your jigs and sleds.

It lets you use stop blocks so you can make repeatable cuts…

Hold-down clamps to steady boards and keep your fingers out of harm's way…

And even let you create adjustable fences for tools like a router table.

But when you get creative, you realize there are actually other ways to use t-track that aren’t common — but still super useful.

Got some t-track laying around? Here’s 4 weird ways to put it to use.

1. KEYS FOR SHOOTING BOARD FENCES

I like to build shooting boards with removable fences that can be switched out and locked into place.

This lets you create fences for specific angles — and just offers a lot more versatility.

The best way to do this is with a “key” that locks into a groove in the bottom of the fence.

And t-track makes an excellent shooting board key.

Because standard t-track is exactly ¾” wide, it fits into ¾” grooves perfectly — tight enough to hold your fence steady, but not so much that it’s hard to remove.

As a bonus, you only need to cut a groove in the fence and not the base!

2. STRAIGHT EDGE FOR JOINTING

Need to joint the edge of a small board? Grab a line of t-track.

As long as the t-track is as long or longer than the board, you can use it to help you accurately joint one edge with either a table saw or a router.

Start by laying a strip of double stick tape on the bottom of the t-track. Then…

-

Router: Set the t-track so it’s just shy of the edge of the board along its length. Then put a flush trim bit in your router and set it so the bearing rides along the t-track. Make the cut!

- Table Saw: Set the t-track on the board so it slightly hangs over the edge. Now you can run the edge of the t-track along your fence and make a rip cut along the opposite side of the board.

3. WINDING STICKS

If you ever flatten boards with a hand plane, you know all about winding sticks.

And because of their consistent width, t-track makes for super quick and accurate winding sticks.

Use a sharpie or spray paint to add a contrasting color to the corners of one piece of t-track.

Then place it over the face of the board you’re flattening towards the back with another piece of t-track towards the front.

As you lower your gaze, you’ll be able to see if there’s any twist in the board’s plane — and know how to proceed to get it flat.

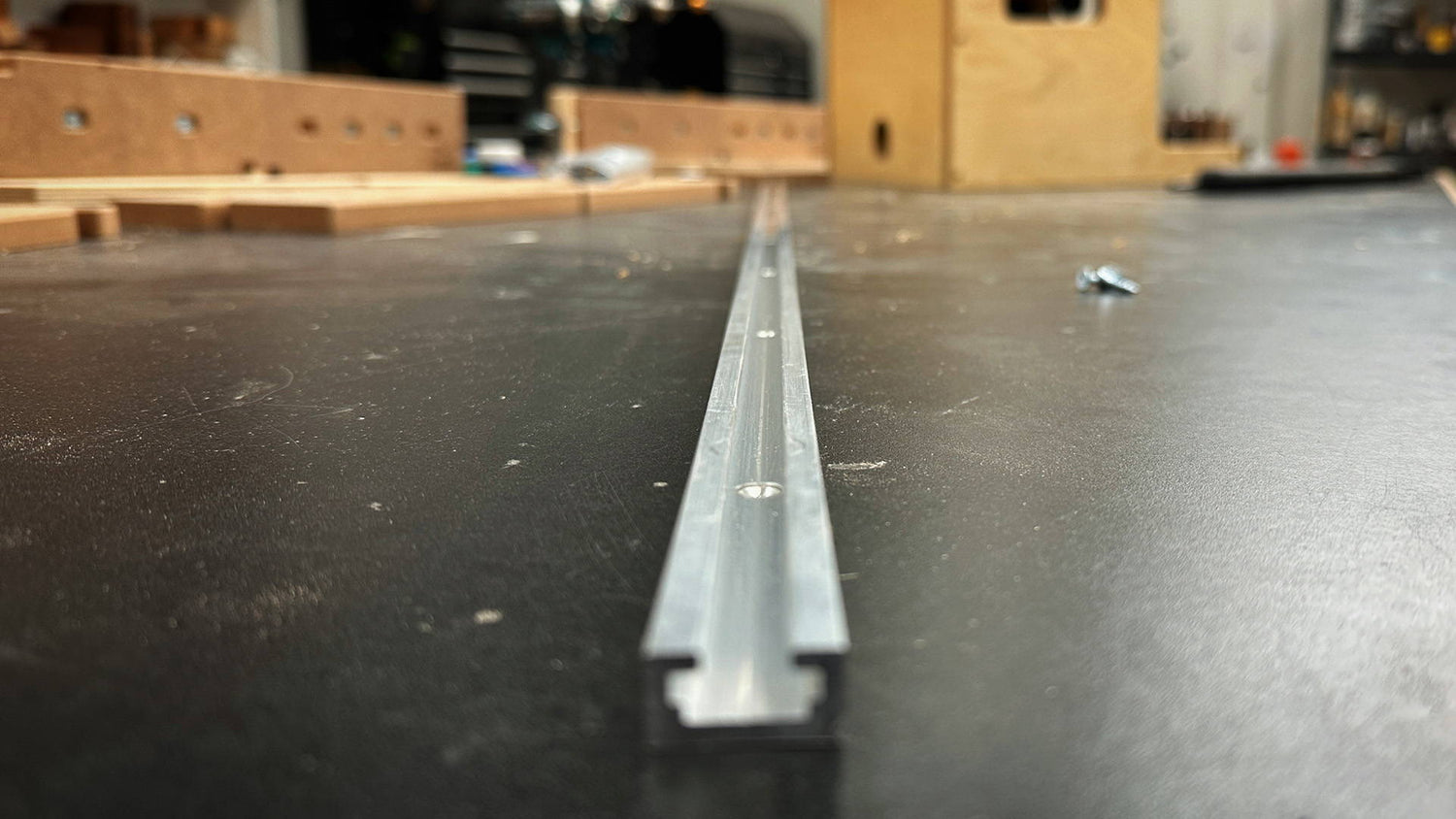

4. MITER SLOT RUNNERS FOR SLEDS

This is my favorite weird use for t-track — and works ridiculously well.

Because of their ¾” width, t-track makes for PERFECT miter slot runners on your table saw sleds.

And the t-track we carry even comes with pre-drilled countersunk holes and screws for easy installation.

But the best part is since it’s made from aluminum, t-track isn’t subject to seasonal expansion and contraction like wood.

That means you don’t need to worry about your sled runners suddenly becoming too tight to push — or too loose to be accurate.

TIP: T-track will probably have a little bit of play in most miter slots. To get rid of slop, push the ends on the two runners away from each other as you attach them to your sled. This eliminates any play.

Want to know how fence clamps can make your time in the shop easier? Read this.

What other weird uses for t-track can you think of? Let us know in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

4 comments

Mark Terry

Has anyone ever tried installing T-track on the ceiling joists from their shop, and attaching power extension leads or a fan or heater to T-bolts, so that you could move them around your shop? Seems like it would work great just as long as the T-track and T-bolts could hold the weight and not get deformed from being clamped for long periods of time.

Has anyone ever tried installing T-track on the ceiling joists from their shop, and attaching power extension leads or a fan or heater to T-bolts, so that you could move them around your shop? Seems like it would work great just as long as the T-track and T-bolts could hold the weight and not get deformed from being clamped for long periods of time.

Kevin

It’s important to note that not all T-track is the same. Most, like yours, is 3/8” deep. However I find that the 1/2” deep T-track is sometimes more useful. It is stiffer, if you are using it as a straightedge or winding sticks. More importantly, when making jigs and router/drill press tables out of multiple layers one can simply make the top layer out of 1/2” MDF or plywood and arrange the T-track between pieces of the top pieces, eliminating the need to rout or dado grooves to receive the track.

It’s important to note that not all T-track is the same. Most, like yours, is 3/8” deep. However I find that the 1/2” deep T-track is sometimes more useful. It is stiffer, if you are using it as a straightedge or winding sticks. More importantly, when making jigs and router/drill press tables out of multiple layers one can simply make the top layer out of 1/2” MDF or plywood and arrange the T-track between pieces of the top pieces, eliminating the need to rout or dado grooves to receive the track.

Anonymous

Blue tape works to help tighten a loose runner

Blue tape works to help tighten a loose runner

Anonymous

In the extremely rare case when t-track might be loose, another way to tighten it is to use either a spring-loaded center punch or a pointed punch and hammer to create a “dimple” on the side of the t-track. When the indention is created the aluminum around it has to go somewhere, so it raises a small rim around the indention. Care should be taken to not get carried away with your strength behind the hammer, as it takes only a little to increase the width of the t-track. If after creating the dimple one finds that the track is too tight in its slot, one can run the t-track back and forth in the slot until reaching the perfect place where there is no play and sliding is not difficult.

In the extremely rare case when t-track might be loose, another way to tighten it is to use either a spring-loaded center punch or a pointed punch and hammer to create a “dimple” on the side of the t-track. When the indention is created the aluminum around it has to go somewhere, so it raises a small rim around the indention. Care should be taken to not get carried away with your strength behind the hammer, as it takes only a little to increase the width of the t-track. If after creating the dimple one finds that the track is too tight in its slot, one can run the t-track back and forth in the slot until reaching the perfect place where there is no play and sliding is not difficult.