While it’s not the sexiest piece of equipment in your shop — it’s one of the most important.

But for a lot of woodworkers, it’s an afterthought. Especially if you're just getting started.

I’m talking about dust collectors.

Every time you sand, chop, cut, or route, you generate piles of sawdust. And knowing how to manage it all matters beyond a shiny, Instagram-ready shop...

Your health depends on it. Because as much as you love woodworking, I’m willing to bet you love your lungs more.

Today, I’m going to tell you:

- Why dust collection matters in your woodshop

- The pros and cons of different dust collection systems

- My Top 7 hard-earned pro-tips for setting up your own full-blown dust collection system

That pun’s a freebie.

I’ve also got some super helpful videos, templates, and build plans you can check out to make your dust collection system as effective and user-friendly as possible.

French Cleat Dust Collection Switcher

DIY Dust Collection Blast Gates: 4” and 6”

Dust Collection Install with Lots of Tips and Tricks

WHY DUST COLLECTION IS IMPORTANT

Some people say lungs full of sawdust are a woodworker's right of passage.

They probably also rail against seat belts in their free time.

The truth is, unprotected exposure to sawdust can lead to all sorts of nasty health issues.

And the worst kind of wood dust? You can’t even see it. I’m talking under 10 microns in size, which is 10x smaller than the thickness of a single hair from your head.

So, if your current sawdust solution is a broom, or you find yourself sneezing a lot after time in the shop… you best be taking notes.

STEP 1: WEAR PROTECTION

Public service announcement: Normal dust masks DO NOT protect you from fine wood dust.

The small particles pass right through the fabric and into your lungs.

To fully protect yourself, you need a respirator mask that can filter out small particulates in the air. These are the kind with replaceable filters you switch out every so often.

We have a couple of comfortable and badass-looking RZ Masks in our store that filter out particles as small as 0.1 microns. I always wear mine when I know I’ll be spewing sawdust.

But if appeals to your health don’t work, consider this:

Wood dust and wood chips are bad for your woodworking. They can clog up your tools, shortening their lifespan and accuracy.

Your sleds can get caked in it, offsetting your stock and making it impossible to get clean cuts.

Stray dust can even settle into your glue-ups and stop you from getting ultra-tight joints, or make it impossible to get perfect finishes.

Now, let’s find a dust collection system that’s right for you.

TYPES OF DUST COLLECTION: PROS AND CONS

From DIY systems made of shop vacs and buckets, to dedicated dust collectors with multiple lines and splitting ducts, you’ve got options for how to suck up the sawdust caking your tools.

Finding the best system for your needs will depend on your budget, tools, and the size of your shop.

But whatever you go with — it’s better than a broom.

SHOP VACUUMS

These are many a woodworker’s first foray into the world of dust collection. That’s for two reasons: convenience and affordability.

Most shop vacuums cost around $100, making them super budget-friendly. They don’t take up much space, are easy to move, and the set up time is about as long as it takes you to open the box.

The problem is, they don’t work well for everything.

With suction power hovering around 150 cubic feet per minute (CFM), they’re great for handheld tools or when you get the hose right next to the source of wood dust.

But on bigger tools like your table saw, the dust ports are too far away, and a shop vac won’t do much to really protect your lungs.

It’s better than nothing — but definitely still requires a respirator mask.

And if you’ve thought about setting up a multi-line hose system for all your tools… Pretty much no shop vac is going to have the suction power to be effective across multiple, long lines.

Pros:

- Most affordable dust collection system

- Takes up very little space in the shop

Cons:

- Not enough power to be super effective on bigger tools

- Not effective for multi-line systems, leaving you switching the hose from tool to tool

SINGLE STAGE DUST COLLECTORS

This is where you start getting into serious dust collection.

For a price jump as low as $100, you can get over 3x the suction power with a machine that sucks 500 CFM.

This is the place to start if you’re looking into a shop-wide system of hoses that run to each tool.

But the limitation of single-stage dust collectors is right in the name.

When one of these machines sucks in wood dust, everything goes straight to the filter—tiny bits of dust, wood chips, screws, your neighbor’s cat — you name it.

This clogs up the filter fast.

Not only are you going to have to clean and replace the filter more often. It’s also going to reduce the suction of your machine — meaning less effective dust collection.

Pros:

- Reasonably priced in the $300-600 range

- High suction capacity that’s good for multiple hoses around the shop

Cons:

- Filter gets clogged up quickly, reducing suction ability and requiring constant cleaning/replacement

TWO STAGE DUST COLLECTORS

Two stage dust collectors are the ultimate wood dust suckers. They fully exploit the laws of aerodynamics to extend the lifespan of your filter and the power of your machine.

Instead of going straight to the filter, the wood particles first go into the cyclone: a tapered, cylindrical tank that makes air move like a — what’s the word…

As the air in the tank spirals, the heavier wood chips fly out towards the edge. They eventually hit the sides of the tank, lose velocity, and fall into the bag or bin below.

The really small dust particles get sucked up into the filter. Less material going to the filter means it won’t get clogged as quickly and your machine keeps sucking at full power.

Pros:

- Cream-of-the-crop of dust collection

- Run better and for longer than other options

Cons:

- Usually going to set you back at least $1000

HONORABLE MENTION: CYCLONE ADD-ONS

You might have seen cyclone add-ons you can incorporate into your existing single-stage dust collector — effectively making it into a two stage dust collector.

I highly recommend doing this, as it will help keep your filter from clogging up too quickly and slowing down your machine.

But there’s a misconception that add-on cyclones will increase the sucking power of your machine. They won’t. But they will help your machine keep running at optimal suction.

HOW TO SET UP A FULLY-FLEDGED DUST COLLECTION SYSTEM IN YOUR SHOP

You don’t need to be an expert in fluid dynamics to set up a good dust collection system that’ll keep your shop and lungs dust-free.

I’ve done it twice now, learned from my mistakes, and I’ve got plenty of tips to make it super easy for you.

TIP #1: CHOOSE THE RIGHT DUCT MATERIAL

These are going to make up the main lines of tubing running from your dust collector to your tools.

My favorite option is 6 inch thin wall pvc and 4 inch sewer drain pipe. They’re both strong, affordable, and their smooth interiors create good airflow.

Steel ducts are great, but a lot more expensive. And don’t make the mistake of buying HVAC tubing. It’s not all designed for dust collection and will leak like crazy.

Also, don’t go ham with flexible tubing. The little ribs really slow down the airflow.

In my recent Dust Collection Switcher video, I got A LOT of comments about all the flex tubing. What we neglected to show on camera was how close all the tools were to the switcher. The longest run of flex hose was 3 feet and most of them less than 2. In addition, there is 6” ducting run from the dust collector to the switcher that terminates 12 inches to the left.

When attaching the tubing to your ceiling or walls, metal pipe strapping makes it dead simple. Tire wire works too.

TIP #2: KEEP IT BIG AND LONG

It’s best to keep your tubing as big in diameter as possible for as long as possible.

Use the 6 inch PVC up until it’s right next to your tools. Then, switch over to the 4 inch pipe to get the run even closer. Finally, use short runs of flexible hose for connecting to your tools.

This ensures that you’ve got maximum airflow throughout the entire run.

TIP #3: STRAIGHT, SIMPLE, AND BORING IS BEST

To get your machine running it’s best, you want the first run of tubing coming out of the dust collector intake to be as long and straight as possible.

Airflow doesn’t like sharp turns. It forces a change in direction too quickly, slowing air down and reducing suction. That brings us to a very important point.

Avoid any 90 degree turns when laying out runs of tubing.

No 90 degree shoulders, no T sockets. When I set up dust collection in my old shop, I didn’t think this was such a big deal. Big mistake.

Sharp turns will make your dust collection suck at sucking.

And as we all know, it sucks to suck (gents/ladies points finger*).

Use wye fittings instead, where the offshoot pipe comes out at a 45 degree angle. You’ll still be able to get the runs anywhere in the shop, and you won’t lose suction power.

Overall, the less complex and curvy your duct system, the better.

TIP #4: EMBRACE IMPERMANENCE

Another lesson I learned from my first installation was to NOT permanently fasten the pipes together with PVC cement.

It seems like a good idea at first. But then you inevitably need to change things around, maybe add more tools. I wasted so much PVC from my last duct system because it was all cemented together and couldn’t be taken apart.

On top of that, the fittings are by far the most expensive part. So if you glue in pipes, you won’t be able to reuse them if you relocate your shop or dust collection system.

Just lock the piping together with connectors and seal the edges with high-quality duct tape. It’ll be completely airtight, and you won’t hate yourself if you ever need to move things around.

TIP # 5: DO BLAST GATES BETTER

For a dust collector to be effective, it can only be sucking air through a single line. That means if you have multiple lines running to different tools or tool clusters, you need a way to shut off the lines you’re not using.

That’s where blast gates come in. They create a barrier between a run of piping that can be opened or closed, so you only get suction to the tool you're currently using.

When opened, a blast gate lets air and suction through. Close it, and you kill the airflow.

But the metal blast gates most people buy don’t work all that well. Air seeps out, dust keeps them from closing all the way, and they’re not cheap.

We developed our own DIY wooden blast gates that work way better than the metal ones. They’re cheaper — even when made out of maple plywood — and super simple to make.

They also have a color-coded system that saves a ton of time. With a quick glance around the shop, you can instantly know which blast gates are opened or closed.

You can buy the redrawn plans with step by step instructions and CNC files, and also watch a video where I show you how to put them together.

TIP #6: SET YOURSELF UP TO BE LAZY

This is where shop design and dust collection come together.

If you have a blast gate set up for every tool in your shop, you’re going to spend a lot of time opening and closing them.

Put your blast gates in places that are easy to reach from your tool area and add an identifying mark of red or green so you can see if they are open or closed from afar. I like to add green and red paracord to my shop-made gates.

If you have a large shop like mine, it’s also a good idea to have main gates for each cluster. That way, if you’re jumping back and forth from clusters you can just shut down the whole cluster without having to bend over behind your tool.

This will improve the suction power of your machine. It’s also way less of a hassle and lets you be lazy. Big win.

I’ve just come with a mind-blowingly simple and effective dust collection line switcher that lets you be ultra lazy.

It attaches to your shop wall with french cleats (so hot right now) and uses a slider that lets you switch which runs your dust collector’s sucking from.

You can set it up to go to tool clusters or individual tools, and it dramatically cuts down the number of blast gates you need.

If you want to set one up yourself, here’s everything you need:

TIP #7: INSTALL A FLOOR SWEEP

It’s awesome. You’ll be glad you did.

Got any dust collections tips, questions, or just want to vent about how loud your shop vacuum is? Leave it in the comments below.

For company questions or customer service, you can email us at support@kmtools.com.

As always, STAY SAFE IN THE SHOP.

As a reminder, we offer affordable tools you need to take on any project with confidence

Don’t forget that for this build we recommend you grab:

16 comments

Robert K

Seems like gravity would rob some CFM by having all those pipes overhead. Maybe raised flooring with pipes underneath would be better for those with the budget. Could get such flooring from decommissioned data centers.

Seems like gravity would rob some CFM by having all those pipes overhead. Maybe raised flooring with pipes underneath would be better for those with the budget. Could get such flooring from decommissioned data centers.

chaosdsm

You mentioned to not use HVAC tubing because it leaks???? Sheet steel HVAC tubing does not leak unless it is incorrectly installed. Seams in HVAC tubing should be sealed with mastic (basically a fiber reinforced adhesive paste) and aluminum HVAC tape once the mastic has dried (24 to 72 hours depending on brand & formulation) and results in zero leakage for life. Straight seems in HVAC tubing also cause less disturbance to airflow vs the spiral seams found on common dust collection metal tubing.

You mentioned to not use HVAC tubing because it leaks???? Sheet steel HVAC tubing does not leak unless it is incorrectly installed. Seams in HVAC tubing should be sealed with mastic (basically a fiber reinforced adhesive paste) and aluminum HVAC tape once the mastic has dried (24 to 72 hours depending on brand & formulation) and results in zero leakage for life. Straight seems in HVAC tubing also cause less disturbance to airflow vs the spiral seams found on common dust collection metal tubing.

Eric Trion

Really like the wooden blast gate – easier to use than the standard metal and screw system. Great article.

Really like the wooden blast gate – easier to use than the standard metal and screw system. Great article.

Graham

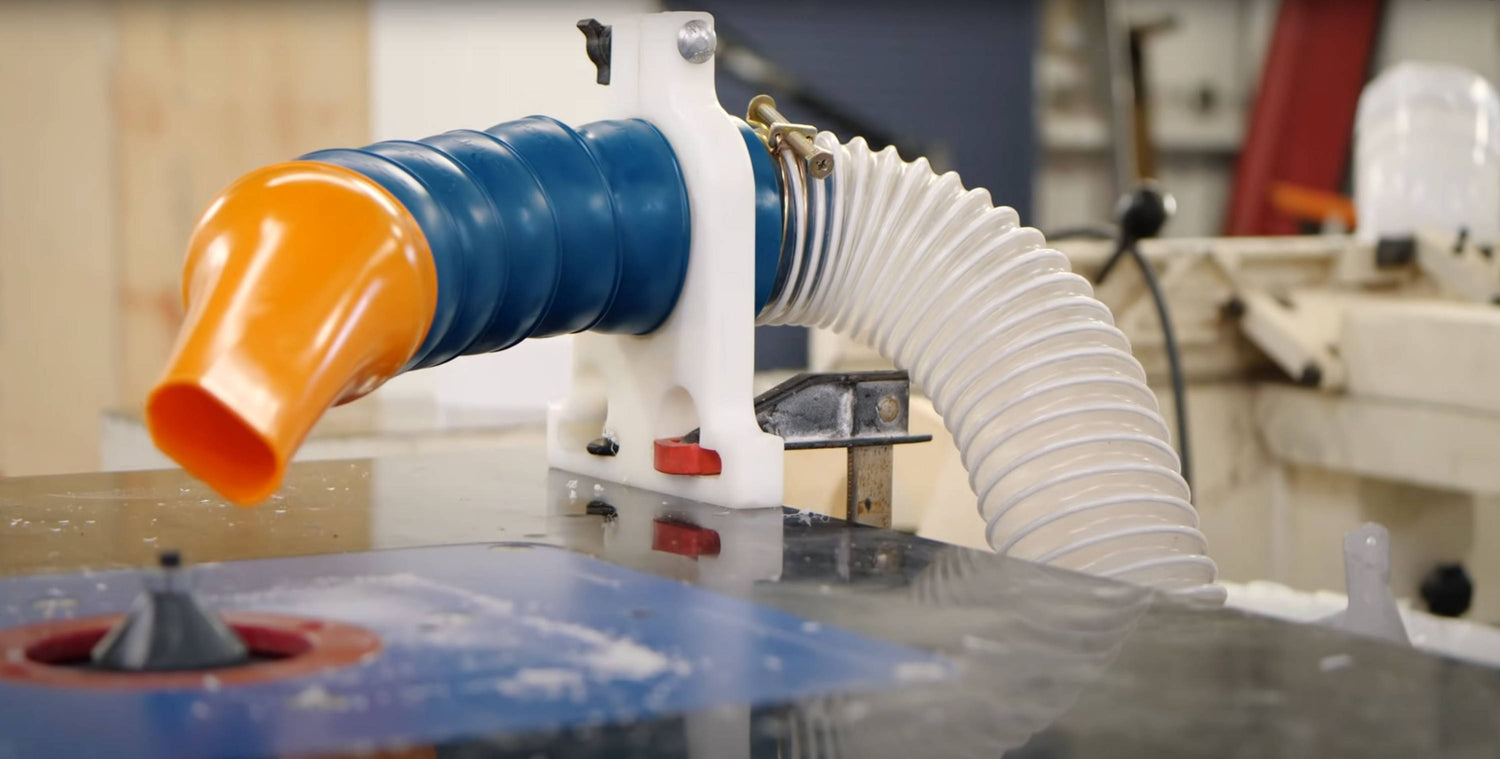

Where can I find that white mount for the loc line at your router table?

Where can I find that white mount for the loc line at your router table?

Jonathan Katz-Moses

Thanks for the comments, everyone!

@Peter: I got it with a dust collector on Craigslist so I do not know.

@Corey: As long as the ducting doesn’t leak, you should be good.

@Gavin: You do not need to ground your system. There’s an amazing video on YouTube from an electrical engineer named John McGrath who is also a woodworker. He proves beyond any doubt that grounding your system is pointless.

@Andy: I would measure the diameter of the opening and search using that measurement.

Thanks for the comments, everyone!

@Peter: I got it with a dust collector on Craigslist so I do not know.

@Corey: As long as the ducting doesn’t leak, you should be good.

@Gavin: You do not need to ground your system. There’s an amazing video on YouTube from an electrical engineer named John McGrath who is also a woodworker. He proves beyond any doubt that grounding your system is pointless.

@Andy: I would measure the diameter of the opening and search using that measurement.

Peter

Where can I find a plan or purchase the bracket holding the hose over the router table in the first photo?

Great information for this hobbyist wood worker

Where can I find a plan or purchase the bracket holding the hose over the router table in the first photo?

Great information for this hobbyist wood worker

Corey

You mention steel ducts are great but more expensive, but to not use HVAC tubing. Is the HVAC tubing you mention referring to flexible duct? Would a standard galvanized steel duct pipe (like something you’d use to vent a dryer) work and avoid the issues you’re referring to with the HVAC tubing?

You mention steel ducts are great but more expensive, but to not use HVAC tubing. Is the HVAC tubing you mention referring to flexible duct? Would a standard galvanized steel duct pipe (like something you’d use to vent a dryer) work and avoid the issues you’re referring to with the HVAC tubing?

cynthia, occasional MD

Thanks for instructions on preventing an under appreciated cause of lung cancer.

Thanks for instructions on preventing an under appreciated cause of lung cancer.

Anonymous

Jonathan, I have heard it said that the PVC piping can be a danger with static electricity and dust and somehow these need to be ‘earthed’ is that correct ?

Jonathan, I have heard it said that the PVC piping can be a danger with static electricity and dust and somehow these need to be ‘earthed’ is that correct ?

Peter

Jonathan,

Wonderful article and useful tips. One BIG lung killer is the stupid dust bags. Most only filter to 2 microns, some are better but at 1 micron. Still that stuff can kill you. I vent my dust collector outside my building and installed the motor in the attic. There’s a chip/dust separator in-between utilizing 45 gallon round heavy-duty trash cans. It’s a huge difference plus its tons quieter. Plus, I don’t need to clean the stupid bags anymore which did nothing more than restrict airflow as they progressively got clogged.

Also, I built 300 CFM shop air filter using a permanent 24 × 24 washable filter and twelve 6 inch 120V computer fans. It’s mounted on the ceiling, intake is on the bottom and discharge is in four directions. It keeps the air super clean. Easy built too.

Jonathan,

Wonderful article and useful tips. One BIG lung killer is the stupid dust bags. Most only filter to 2 microns, some are better but at 1 micron. Still that stuff can kill you. I vent my dust collector outside my building and installed the motor in the attic. There’s a chip/dust separator in-between utilizing 45 gallon round heavy-duty trash cans. It’s a huge difference plus its tons quieter. Plus, I don’t need to clean the stupid bags anymore which did nothing more than restrict airflow as they progressively got clogged.

Also, I built 300 CFM shop air filter using a permanent 24 × 24 washable filter and twelve 6 inch 120V computer fans. It’s mounted on the ceiling, intake is on the bottom and discharge is in four directions. It keeps the air super clean. Easy built too.

Richard Bentley

Very nice blog, thank you.

Very nice blog, thank you.

Anonymous

I’m working on programming a water cooled computer this weekend, and missing the old woodshop. So, this was a nice break and made me feel that I am almost back at woodworking. Good timing.

P. S. I could use all the swear words that anybody can spare.

I’m working on programming a water cooled computer this weekend, and missing the old woodshop. So, this was a nice break and made me feel that I am almost back at woodworking. Good timing.

P. S. I could use all the swear words that anybody can spare.

Diane

I purchased and made your blast gates. Really a nice system and would highly recommend them. My vertical runs are along walls and had to do some creative brackets to affix to the wall, but otherwise operate great! Thanks, Jonathan!

I purchased and made your blast gates. Really a nice system and would highly recommend them. My vertical runs are along walls and had to do some creative brackets to affix to the wall, but otherwise operate great! Thanks, Jonathan!

Anonymous

I built a Thien baffle separator for my shop system, but it still uses the leaky filter bag. I there a way to calculate what size pleated filter I would need to replace the bag?

I built a Thien baffle separator for my shop system, but it still uses the leaky filter bag. I there a way to calculate what size pleated filter I would need to replace the bag?

Vernon

I am an occasional woodworker, so I’ll probably never have a proper dust collection system, but I really appreciate all the advice nonetheless. Thanks Jonathan & team.

I am an occasional woodworker, so I’ll probably never have a proper dust collection system, but I really appreciate all the advice nonetheless. Thanks Jonathan & team.

Hugh

I Kats-Moses myself and built this amazing sled (using the KM Stop & track) and it came out amazing. Being square is a good thing!! Directions and callouts were extremely helpful. Love it.

I Kats-Moses myself and built this amazing sled (using the KM Stop & track) and it came out amazing. Being square is a good thing!! Directions and callouts were extremely helpful. Love it.