Ever been tempted to delve into traditional hand tool woodworking? There’s no better combo than a drawknife and shavehorse.

Shavehorses are the traditional “workbenches” of drawknives (and spokeshaves).

With a clamping mechanism that locks down by pushing with your feet, they let you quickly rotate and check your workpiece — without having to loosen and tighten a vise again and again.

Even better, they give you a chance to take a seat while you’re woodworking… a luxury any woodworker will appreciate after hours in the shop.

This dynamic duo lets you turn out spindles and round tenons in no time.

Seriously. You can hammer out a rustic chair or stool in a single day (which is awesome for last minute gifts).

They make for an excellent first project using a drawknife — and are perfect for learning round-tenon joinery (more on that in a future post).

Rex Kreuger has a great video on building an affordable shavehorse out of 2x construction lumber that’s worth a watch.

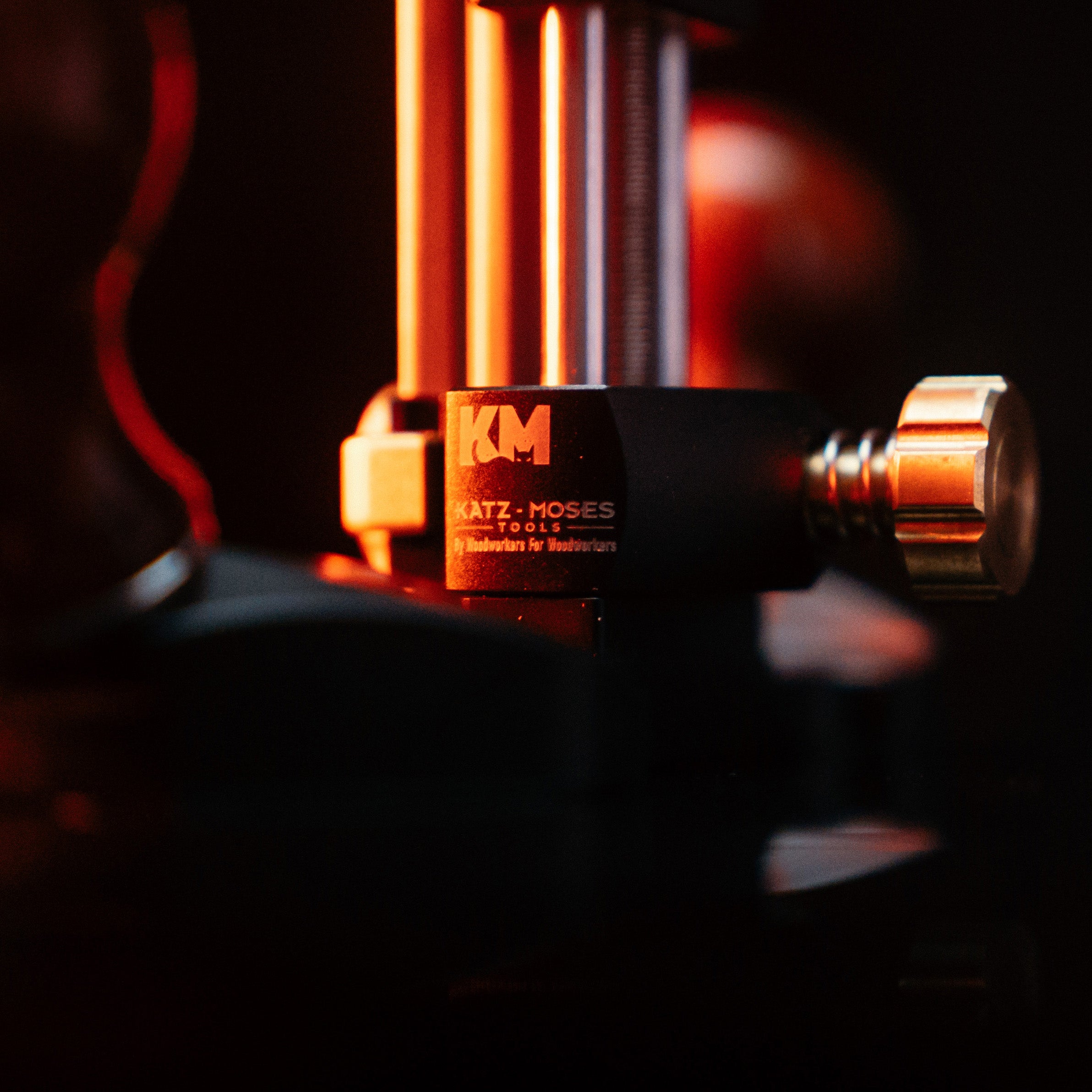

The 10” drawknives we carry are hand-forged with the highest level of craftsmanship — and right now, they’re available for 20% OFF.

With a wear-resistant spring steel blade, figured olive wood handles, and an included olive wood blade cover — it’s sure to be one of the coolest looking tools in your shop.

Already have a shavehorse in your shop? Let us know what you use it for in the comments below!

Follow us on Instagram @katzmosestools, on TikTok @katzmoseswoodworking, and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

3 comments

John

I’ve had spoke shaves in my workshop since as long as I can recall (I am 81 yo), my favourite is Stanley brand that has two wheel adjustments for the blade so it can easily be set up dead squeare or a deliberate tilt applied. The main secret is to keep it as sharp as my Japanese chisels! I also have a very old wooden spkeshave with a curved bottom, useful in boat work.

I’ve had spoke shaves in my workshop since as long as I can recall (I am 81 yo), my favourite is Stanley brand that has two wheel adjustments for the blade so it can easily be set up dead squeare or a deliberate tilt applied. The main secret is to keep it as sharp as my Japanese chisels! I also have a very old wooden spkeshave with a curved bottom, useful in boat work.

Anonymous

Also known as a bodger’s bench. A bodger was a woodworker who made parts for wooden chairs. Often they took orders from companies which assembled, finished and sold the chairs and turned out dozens or hundreds of the same part for their buyer.

Also known as a bodger’s bench. A bodger was a woodworker who made parts for wooden chairs. Often they took orders from companies which assembled, finished and sold the chairs and turned out dozens or hundreds of the same part for their buyer.

Don Duty

Is the blade 10" or is the distance between the outside edges of the handles 10"?

Is the blade 10" or is the distance between the outside edges of the handles 10"?